Active smoke compartment curtain (SC)

Description

The Active smoke compartment curtain forms a mechanic system integrated with the construction which requires little space and allows to control fire smoke and gas movement in a “hidden” way.

- It contains smoke in areas delimited by textiles, avoiding the displacement of smoke to other places not enabled for this purpose.

- It channels the smoke in a certain direction towards the evacuation system.

- Prevents and delays smoke from entering other areas.

- Enables smoke-free spaces.

Material

The system is made up of: a fireproof textile curtain which only unfolds in case of emergency, a galvanized steel box which holds the curtain, a counterweight at the bottom to provide stability, an engine, an engine control module and a panel receiving the fire signals.

Operation

SC1 Curtain compartment is a system with positive security, that is to say, it automatically goes down in a controlled speed after receiving a signal from the fire detection system. Lowering can be done in two phases, with or without electrical current

Applications

Buildings where it is not possible to install a fixed barrier due to aesthetic reasons:

– Shopping Malls

– Public buildings

– Garages

– Airports

– Museums

Classification

SC1 Curtain has been tested and certified in an official laboratory with a D120 temperature/time classification (600 ºC for 120 minutes) ASB1 and 3 according to EN 12101-1 and EN 13501-4 standard.

Tested according to UNE EN 1634 “Fire Resistance and Smoke control”.

Tested also according to UL standards.

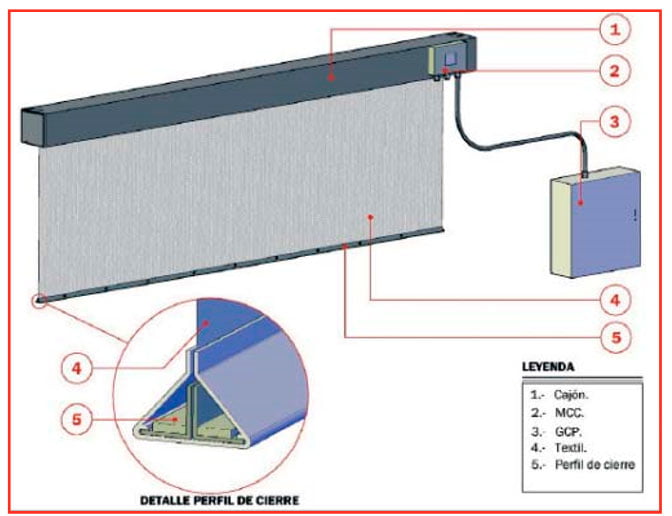

Components

- GCP. The panel responsible for receiving the fire signal coming from the detection system and therefore, activating the curtain. It allows seeing the system state as well as carrying out the maintenance works. It has a system of batteries capable of holding the curtains and electrovalves in the rest position in case of failure from the power supply.

- MCC. Motor control module. Placed next to the engine, it keeps the curtain stable in its rest position (folded). Also, synchronizes the lifting speed and limits the lowering speed under the action of gravity even with power failure.

- Box. Intended to house the fire curtain in its interior, it is made up of galvanized steel 1,5 mm thick. It has several configurations and support systems in order to adapt to the architectural conditions.

- Closing profile. Installed on the lower end of the textile, it provides stability to the whole unit and forms the closing of the box in its rest position

- Textile. Fabric made of fibreglass. United and treated to withstand temperatures up to 1000 ºC.

- Motor. Tubular motor with 24 V DC functioning and operational up to a temperature of 300 ºC. Equipped with a gear system which allows applying the needed touch for the proper functioning of the system.

Additional Components

- Centralisation in touch-screen system with visual representation of state and alarms.

- RAL powder-coated of the metallic elements of the system.

- Acoustic alarm of obstructions in the closing display.

- Manual reset of the system.

- Voice warning of the lowering curtains (optional).

- Warning light of lowering curtains.

- Temporized lowering and/or in stages (optional).

- Temporized escape button (optional).

- Integration contacts with the central management system.

- End of stroke.