Tecwool® 825 Mortar - Steelwork protection

Metallic structures in chemical, petrochemical and power generating plants, among others, are likely to suffer fires generally caused by hydrocarbons.

Tecwool® 825 has been tested pursuant to standard UNE ENV 13381-4, and subjected to UL 1709 temperature curve, to determine its contribution to fire protection when applied to steel structural elements: beams, pillars or tension members.

Tecwool® 825 has been designed and tested to cover a great variety of steel profiles characterised by their section factor. Likewise, it is tested for several design temperatures specified in the standard.

Solution

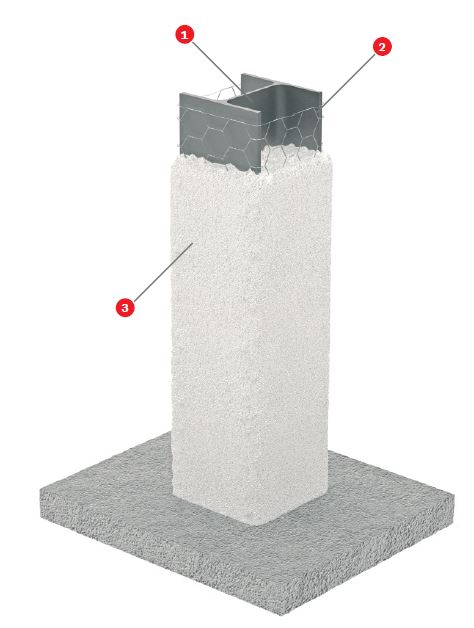

1. Steel profile.

2. Wire mesh.

3. Tecwool® 825 (thickness according to the profi le’s section factor and

fire resistance time required).

Application

Tecwool® 825 is spread with a pneumatic machine pursuant to the following technical specifications:

A wire mesh should be fastened to the support with electro-welded nails or the like, before applying mortar.

The surface to be protected should be free from dust, oil, waste, poorly attached particles, paint leftover, etc.

It is recommended to use water with the application hose to wash dirt away from the faces. This will also help achieve a thermal balance between the mortar and the applied surface.

In structures prone to bumps, a wooden mortar formwork could be installed.

During the spreading, mortar is pressed with a roller in order to render Tecwool® 825 highly robust.