Tecwool® F - Constructive Solutions

Tecwool® F - Carbon fibre protection in structures

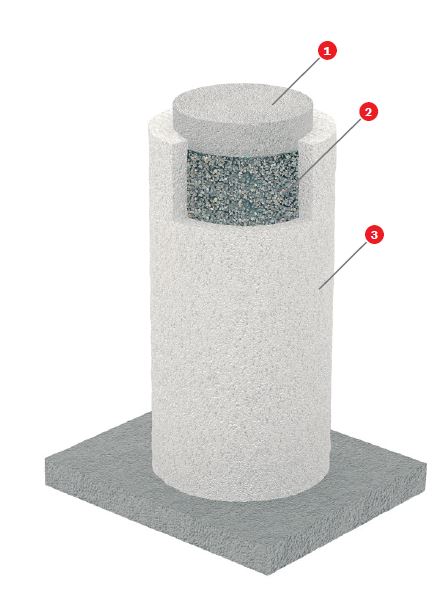

Increasingly often we are seeing concrete columns or beams being reinforced using carbon fibre. This lateral restriction of the concrete improves its strength by reducing cracking by compression and increasing ductility.

This type of reinforcement is typically used in refurbishment work where it is necessary to reinforce the existing structure due to change of use, adaptation to current standards or simply to repair it or make good original defects.

However, carbon fibre and the resins used in its application are extremely sensitive to temperature increases, which often make them unsuitable for performing the functions for which they were designed. Tecwool® F enables the carbon fibre to remain below 81.4 ºC for two hours (for more information please contact our sales department).

Application

The carbon fibre surface must be rough, with this being achieved by sprinkling

silica sand onto the still tacky outer coating of resin. This prevents any problems regarding the bond between the mortar and the resin (please

contact our sales department for more information).

The surface to be protected shall be totally free of dust, oil and/or grease,

loose particles, traces of paint, etc.

It is advisable to give the facing of the structure a light wash down using the

water of the application hose itself in order to remove any remaining dirt. This

shall also ensure that a thermal balance is reached between the mortar and the

applied surface.

Tecwool® F can provide different finishes: rough, smooth, painted, etc. in

accordance with the look required. For smooth finishes, once the application

has been completed a roller must be lightly applied to the damp mortar

until the desired finish is achieved. It is possible to apply elastic acrylic coatings to the mortar to prevent water vapour from penetrating the structure. The mortar must be totally dry (28 days) prior to application.

Following projection, the mortar must be lightly sprayed with water in order

to ensure that the cement hardens in optimum conditions.