Tecwool® F - Constructive Solutions

Tecwool® F - Ceramic block and wooden beams slab structure

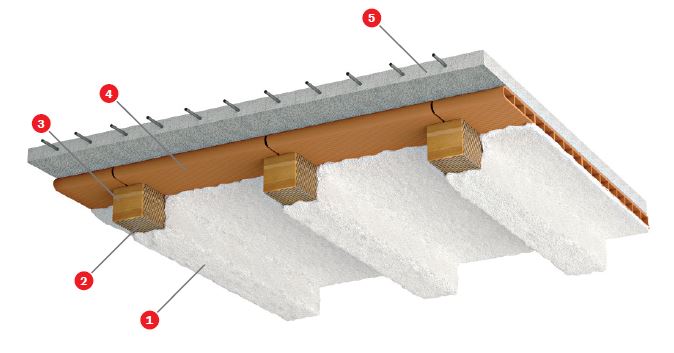

In refurbishment building work, we usually find non-conventional slab structures. In this case, we have a slab structure consisting of a 50 mm thick concrete compression layer under which a hollow ceramic board supported by 140 x 140 mm wooden section beams is placed.

The test was performed pursuant to UNE EN 1365-2. Thermocouples were placed on the compression layer and throughout wooden beams, with the purpose of extrapolating the results to other more favourable configurations,

provided that they remain within the limitations of the above mentioned standard.

For further information, Annex E to DB SI describes a calculation method to determine wooden structural elements’ resistance to the action represented by the standard time/temperature curve. Fire resistance is mainly determined by beam sizes, fi re exposure and the loads supported by them.

Application

Due to wood particular characteristics, Tecwool® F application in this solution differs from other analysed faces. Wood hygroscopicity makes it absorb or release water from the surrounding environment.

To avoid adherence problems from wood shrinking, its surface is covered with a wire mesh fastened with clamps or the like after applying Tecwool® F. mortar.

The mesh acts as reinforcement between the product and the face, providing extra flexibility and adherence to the support structure, regardless of its expansion.

The application on the ceramic block is similar to that on concrete slabs and walls. It is important to verify that there are no holes in slab structure to avoid material waste and to provide the spread with a uniform and homogeneous

finishing.