Tecwool® F - Constructive Solutions

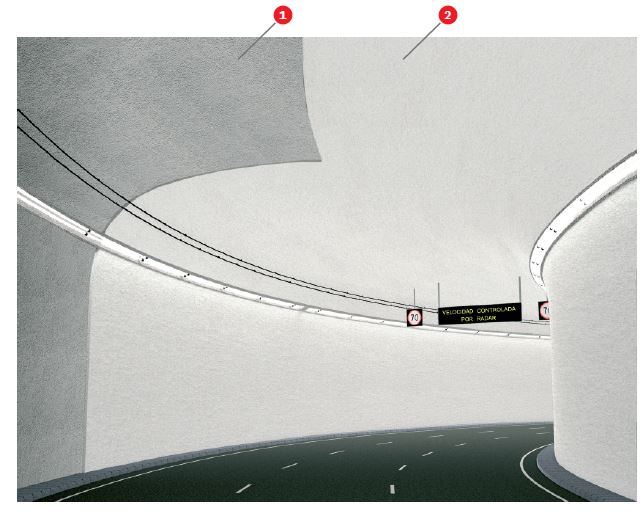

Tecwool® F - Tunnel protection

In case of a fire in a tunnel, material and human damages can only be avoided if the tunnel is adequately protected against fire.

In the last 10 years, several fires in tunnels have occurred worldwide. One of the conclusions is that we cannot simulate fires in tunnels with the same criteria applied to other constructions.

In this case, fires are destructive and reach high temperatures very rapidly. Besides, they can maintain these conditions during long periods of time. In other words, the standard time/temperature curve included in standard UNE

EN 1363-1, representing the pattern of a fire occurring in a certain fi re section, is not suitable for evaluating fires in tunnels.

Consequently, we shall study the effects on materials through fire simulations produced by the combustion of hydrocarbons.

Other effect observed in fi res developed in tunnels is referred to as “spalling” or concrete spalling process. As temperature rises, water in the concrete evaporates. However, steam does not run off properly causing the internal pressure to increase and the layers closer to the fire to spall off.

mercor tecresa® has tested Tecwool® F mortar in a real scale tunnel exposed to a gasoil-caused fire. A 40 mm mortar application was enough to surpass the test performed in San Pedro de Anes by Tunnel Safety Testing S.A.

Application

Tecwool® F is spread with a pneumatic machine pursuant to the following

technical specifi cations:

The surface to be protected requires no prior primer, mesh or any other type of

support for the mortar adherence.

The surface to be protected should be free from dust, oil, waste, poorly attached particles, paint leftover, etc.

It is recommended to use water with the application hose to wash dirt away from the faces. This will also help achieve a thermal balance between the mortar and the applied surface.

Tecwool® F can provide different finishings: rugged, smooth, painted,

etc., according to different aesthetic requirements. Once the spread is completed and in order to obtain a smooth finishing, a roller should be used

and pressed slightly over the wet mortar until the desired finishing is obtained. It is possible to paint the mortar with elastic acrylic coatings to form a steam barrier. Before painting the mortar should be completely dry (28 days).

Once spread, mortar should be water sprayed superficially to ensure optimum

settling of the cement.

Product document

Do you have any questions about the product?

Learn More About...

Tunnel Protection with: