Tecwool® F - Constructive Solutions

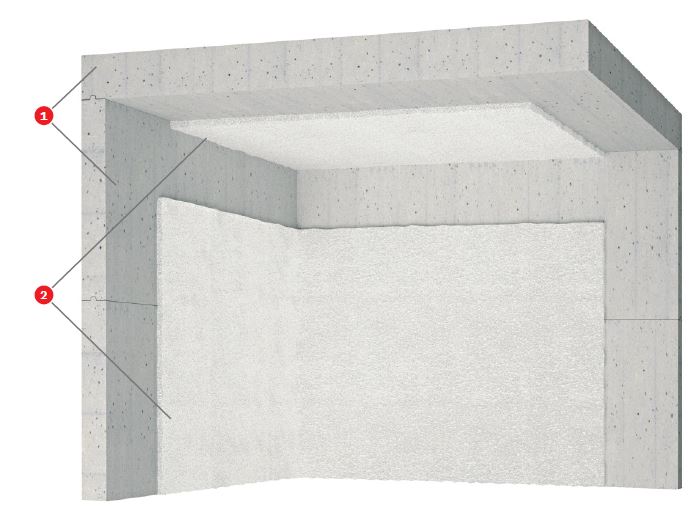

Tecwool® F - Reinforced Concrete Protection

Used in most of modern buildings, concrete is part of today’s landscape because of its multiple applications. However, concrete strength could be seriously impaired when exposed to fire, reducing its resistance when temperature exceeds 300 °C and losing it almost completely above 550 °C. In the case of reinforced concrete, framework resistance decreases after 250 °C, damaging the adherence between steel and concrete.

mercor tecresa® markets Tecwool® F mortar, tested pursuant to standard UNE ENV 13381-3, this test determines its capacity to provide protection against fire, to remain cohesive and fixed to concrete and to provide data on the temperature distribution in the entire protected concrete element when exposed to standard temperature/time curve.

The temperature information obtained in the tests performed is used to provide:

- The relation among concrete temperature, time and thickness of the fi re protection material.

- Concrete equivalent thickness.

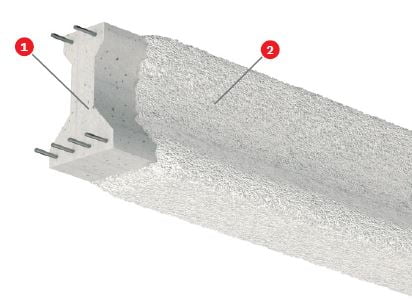

Light, normal or heavy concrete could be used, strength classes being 20/25 (LC/C/HC) to 50/60 (LC/C/HC). The member can contain steel reinforcing bars.

Application

Tecwool® F is spread with a pneumatic machine pursuant to the following

technical specifications:

The surface to be protected requires no prior primer, mesh or any other type of

support for the mortar adherence.

The surface to be protected should be free from dust, oil, waste, poorly attached particles, paint leftovers, etc.

It is recommended to use water with the application hose to wash dirt away from the faces. This will also help achieve a thermal balance between the mortar and the applied surface.

Tecwool® F can provide different finishings:

Rugged, smooth, painted, etc., according to different aesthetic requirements. Once the spread is completed and in order to obtain a smooth finishing, a roller should be used and pressed slightly over the wet mortar until the desired finishing is obtained. It is possible to paint the mortar with elastic

acrylic coatings to form a steam barrier. Before painting the mortar should be

completely dry (28 days).

Once spread, mortar should be water sprayed superficially to ensure optimum

settling of the cement.

Product document

Aplication

Tecwool® F is spread with a pneumatic machine pursuant to the following

technical specifications:

The surface to be protected requires no prior primer, mesh or any other type of

support for the mortar adherence.

The surface to be protected should be free from dust, oil, waste, poorly attached particles, paint leftovers, etc.

It is recommended to use water with the application hose to wash dirt away from the faces. This will also help achieve a thermal balance between the mortar and the applied surface.

Tecwool® F can provide different finishings:

Rugged, smooth, painted, etc., according to different aesthetic requirements. Once the spread is completed and in order to obtain a smooth finishing, a roller should be used and pressed slightly over the wet mortar until the desired finishing is obtained. It is possible to paint the mortar with elastic

acrylic coatings to form a steam barrier. Before painting the mortar should be

completely dry (28 days).

Once spread, mortar should be water sprayed superficially to ensure optimum

settling of the cement.

Product document

Do you have any questions about the product?

Learn More About

Reinforced concrete protection with: