Part 2: Decalogue of a proper sealing apertures and penetrations of electrical service

Actualizado a fecha: 2 December, 2018

6. Plastic Pipes: this type of pipes disappears in the early stages of a fire leaving free space for the pass of smoke and flames. The usual method of sealing such elements is by a metal collar with intumescent product therein. This intumescent product expands up to 11 times its volume completely closing the gap in case of fire. This product is not valid for steel sheet ventilation pipes, unless the section where you will place the multicollar by a PVC pipe is replaced.

7. Seals and small gaps: First of all we must check if we have to sectorize the board or the small hole following that specified by the norm: 50 cm2 and separated more than 3 m from other similar (if not, we must add the surfaces to see if we continue meeting those 50 cm2). If we split them, there are several procedures with different finishes and with different economic cost. There are intumescent putties (similar to silicone), foams (similar to polyurethane foam) and flexible intumescent strips, which fulfill their function to a boundary separation in the tests of each product. For horizontal joint requiring movement, there are Self-leveling Silicones standing with a background of rock wool board.

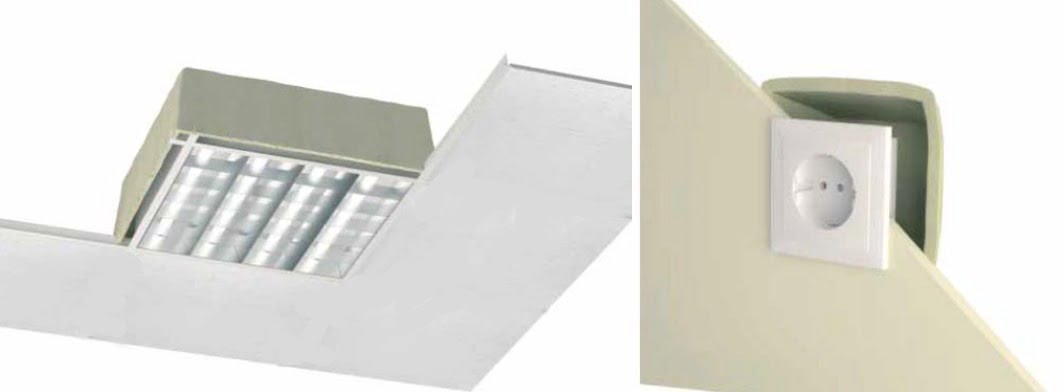

8. Lighting and electrical boxes within sectorizator elements: When making a fire resistant compartmentation (false ceiling or partition), either with plasterboard or Silicate panels, sometimes we need to open holes for the placement of luminaires or electric boxes, without realizing that we are voiding the sectorization and removing a big part of the fire resistance of the ceiling or wall. There are systems to avoid breaking this sectorización that are very simple to install: the luminaire-covers and plugs-covers, graphite materials that are going to give continuity to the sectorization.

9. Natural ventilation in sectorized rooms: When an enclosure sectorized must possess a natural ventilation (eg, data processing center room) and we don’t want to place fire dampers, there are some intumescents grids that allow us that natural ventilation and the completely spread of the grid material before a fire. This system is not suitable for forced ventilation by the characteristics of the material once it has expanded.