Tecbor® Boards - Constructive Solutions

Tecbor® Boards - Steelwork Protection

Steel structures are used for building purposes worldwide. One of the main advantages is that they have great resistance per weight unit, which provides them with huge versatility and the possibility of creating complex yet light

structures.

However, the thermal conductivity of steel represents a disadvantage. Therefore, in the event of a fire, the gradual increase in temperature plus steel high heat transmission result in a substantial reduction of the structure’s bearing capacity and mechanical resistance.

The resistance and elastic limit are modified above 250°C, and above roughly 500°C the drop in resistance is signifi cant enough not to support its design capacity.

mercor tecresa® has conducted numerous tests with Tecbor® according to UNE EN 13381-4, standard, in which is determined the contribution of fire protection of the board when we protect steel structural elements, either on

beams, columns or bearing elements.

Tecbor® has been tested to cover a great variety of steel profiles characterised by their section factors. Likewise, it has been tested for several standard specifi ed design temperatures.

Product document

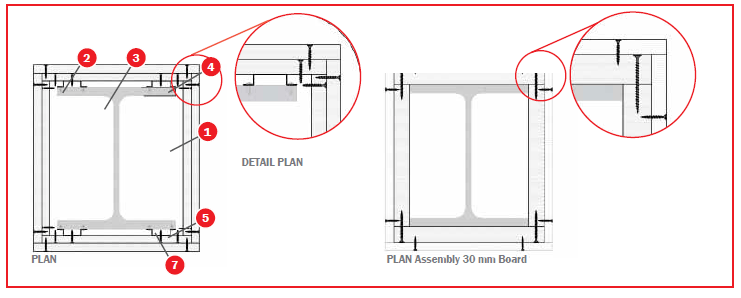

Description of Assenbly

Fix 45x15x0,6 mm omega profiles to the outer side of the metal profile’s flange to be protected with steel nails every 725 mm.

Fix 30x30x0,6 mm lower angle section to the Tecbor® board strips and these onto the omega profiles and onto the angle anchored to the slabs with self-tapping screws every 250 mm.Assemble the strips Use Tecbor® joint paste in screw heads and between boards.

NOTE: If the protection procedure comprises Tecbor® boards with a thickness equal to or greater than 30 mm, they may be joined without auxiliaries using 5 x 80 mm screws at intervals of 250 mm.

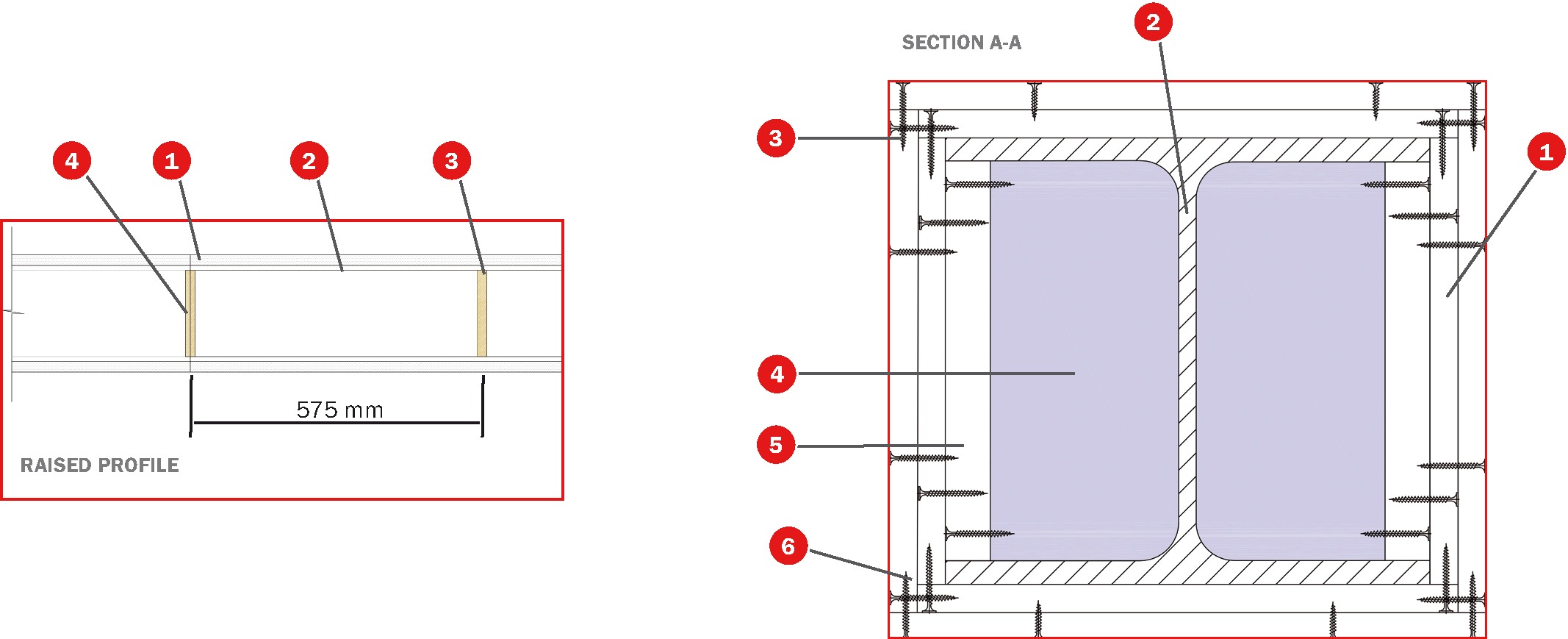

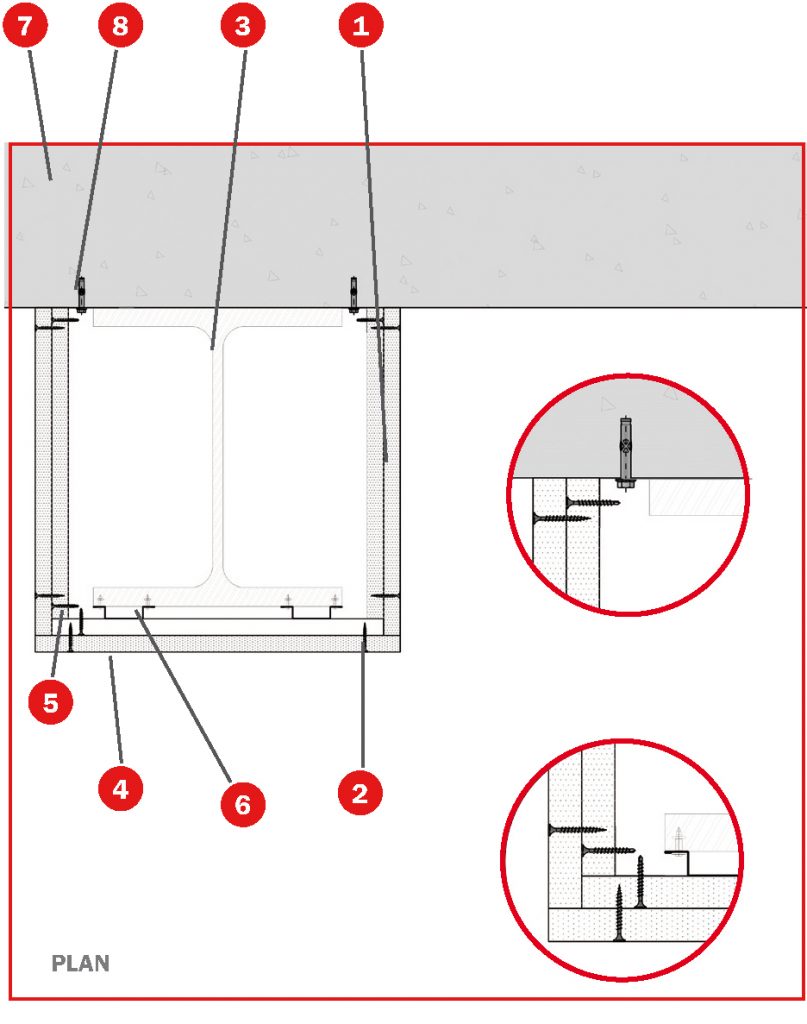

Description of assembly

Fix 45x15x0.6 mm omega profiles to the outer side of the metal profile’s fl ange to be protected with steel nails every 725 mm.

Fix 30x30x0.6 mm lower angle section to the Tecbor® board strips and these onto the omega profiles and onto the angle anchored to the slabs with self-tapping screws every 250 mm.

Use Tecbor® joint paste in screw heads and between boards.

NOTE: If the protection procedure comprises Tecbor® boards with a thickness equal to or greater than 30 mm, they may be joined without auxiliaries using 5 x 80 mm screws at intervals of 250 mm.

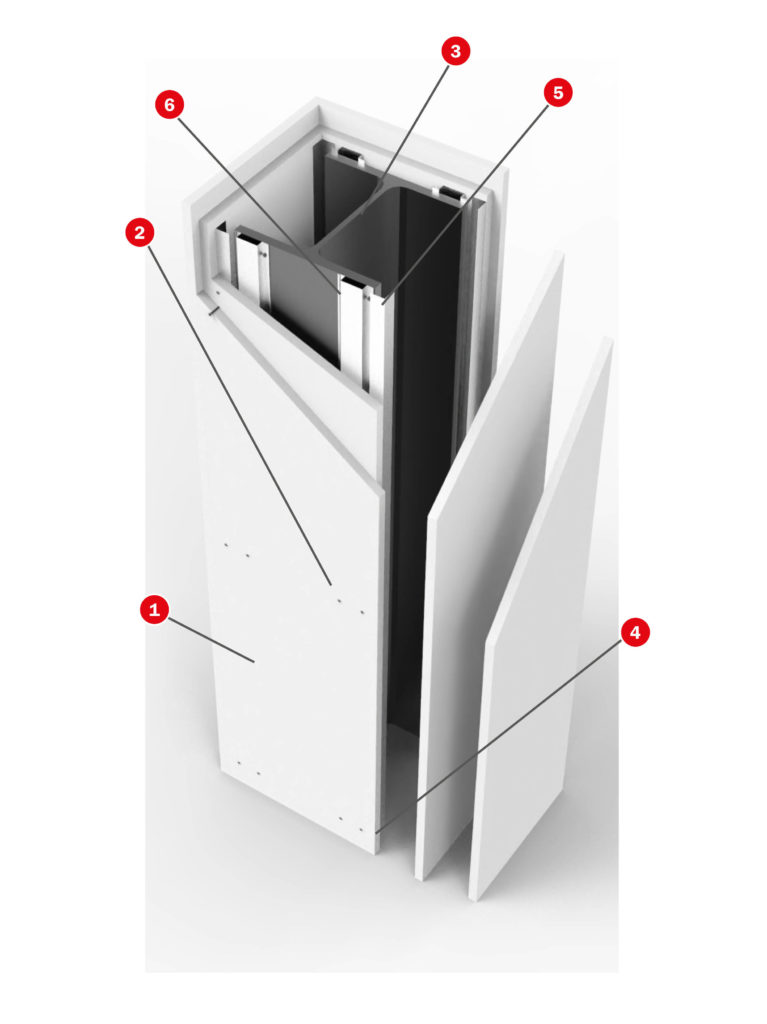

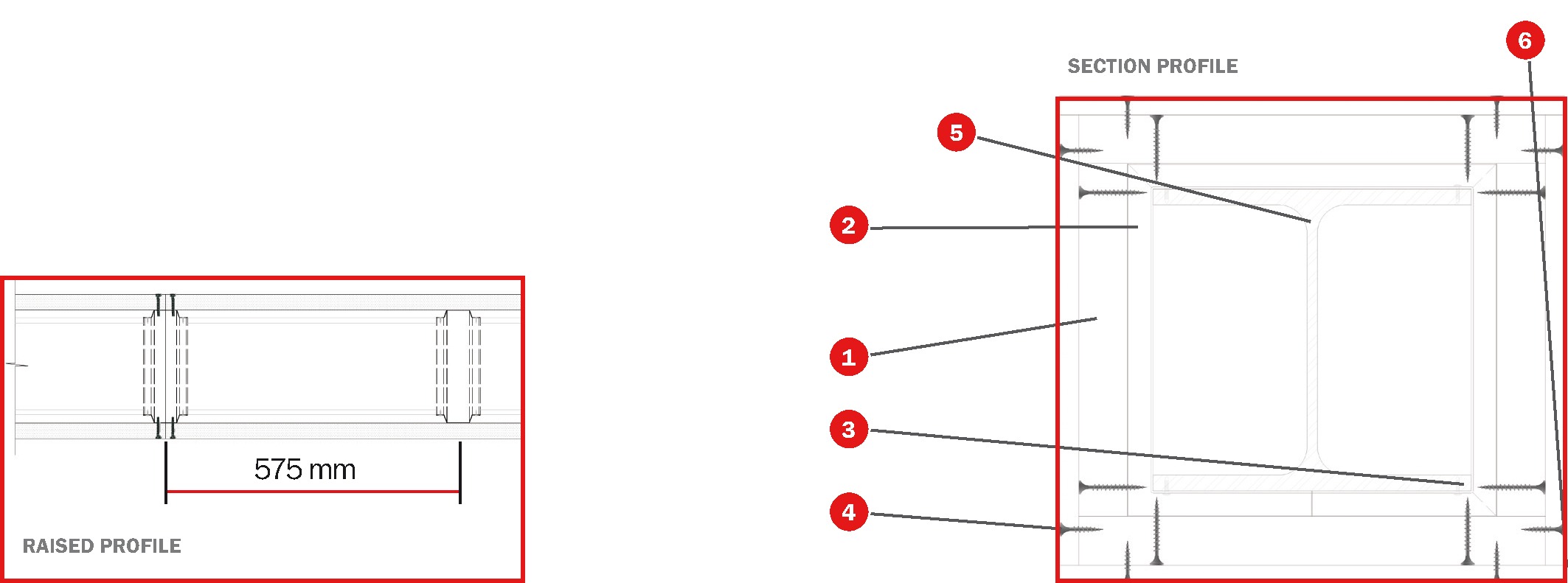

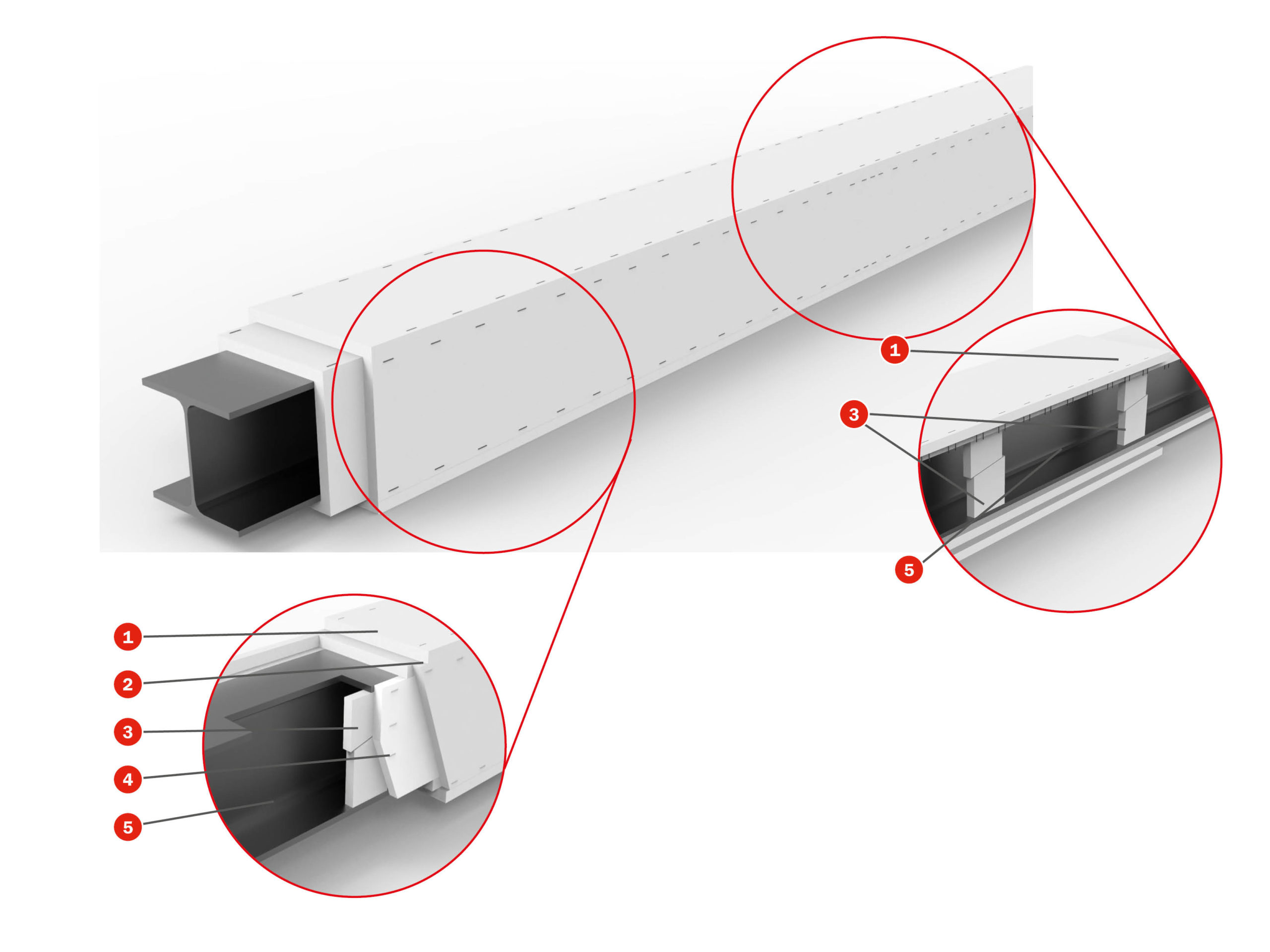

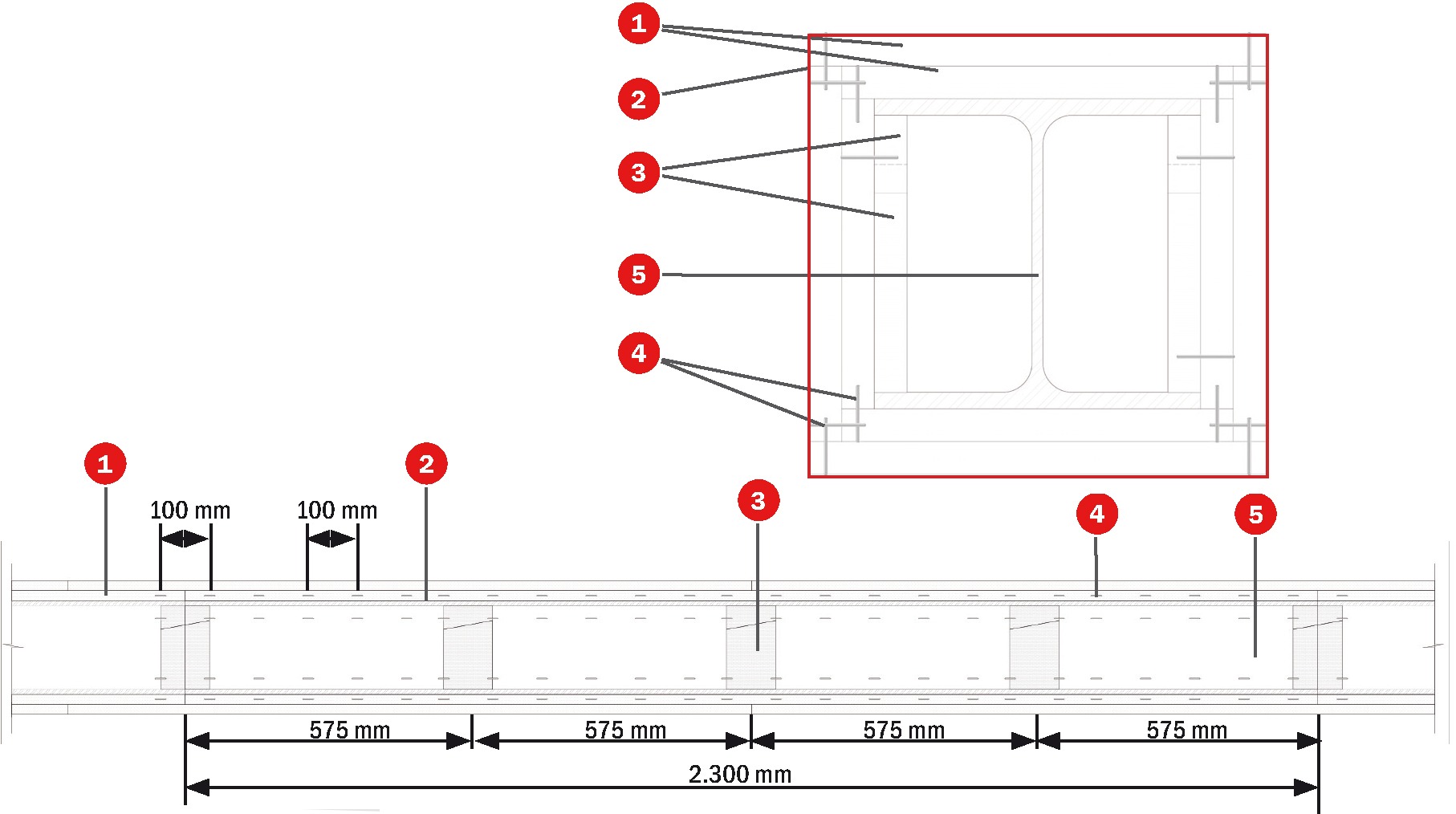

Description of assembly

Attach the 45 x 15 x 0.6 mm omega profiles to the outer side of the flange of the metal profile to be protected using steel nails, and form a ring around it.

The rings will be separated at intervals of a maximum of 575 mm. They will be placed in such a way that the horizontal joints between plates overlap on an omega profile.

Attach the anchored Tecbor® plates to the omega profiles using self-tapping screws every 250 mm.

Use Tecbor® joint paste in screw heads and between boards.

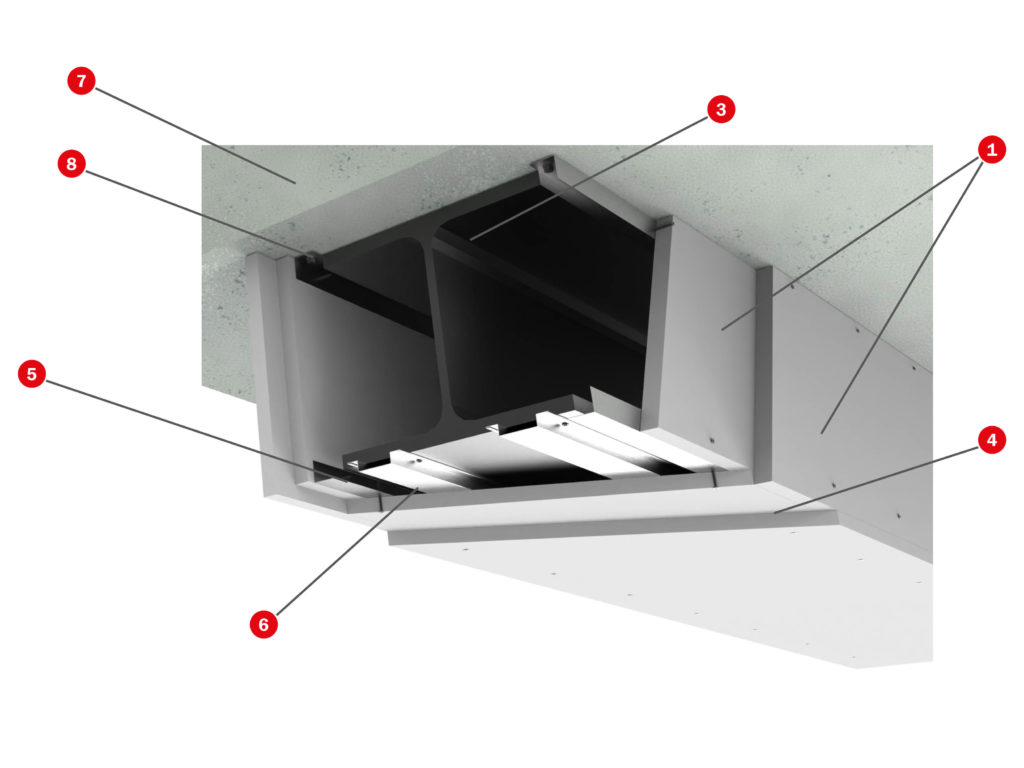

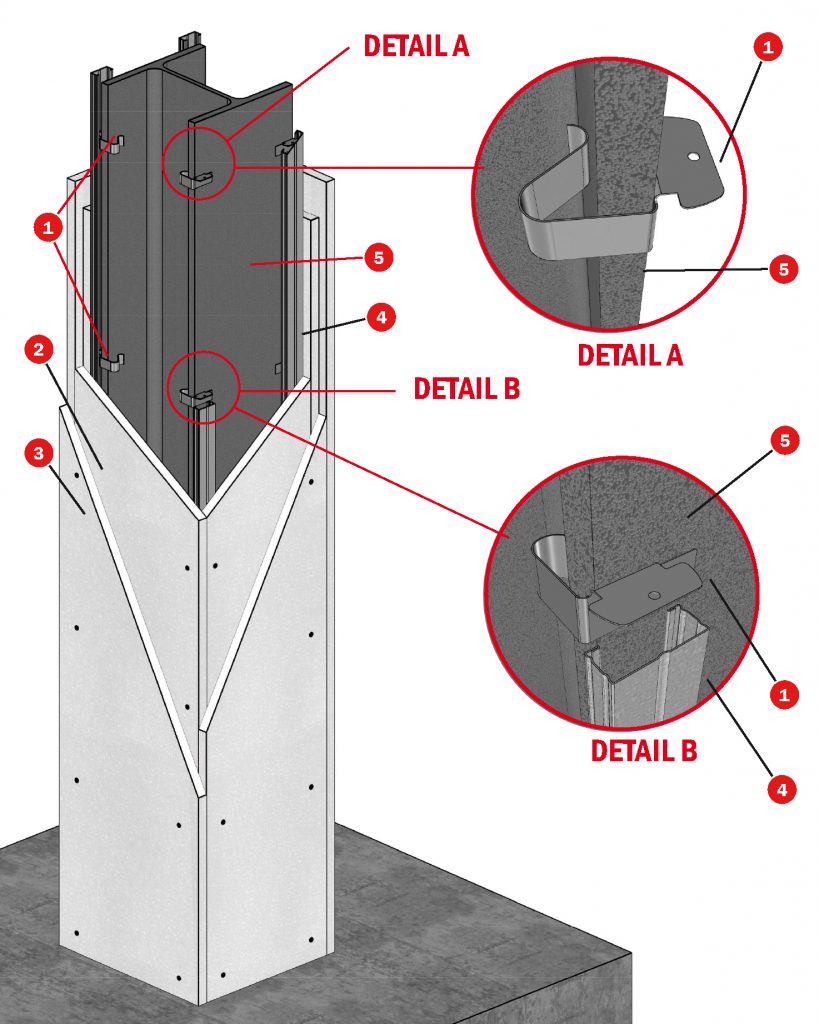

Description of Assembly

Attach the Tecbor® clip to the outer side of the metal profiles to be protected, separated at intervals of no more than 500 mm.

Attach the 45 x 18 x 0.6 mm TC roof profiles to the Tecbor® clip by pressure.

Attach the anchored Tecbor® plates to the TC profiles using self-tapping screws every 250 mm.

Use Tecbor® joint paste in screw heads and between boards.

Description of Assembly

Fijar los perfiles omega 45x15x0,6 mm en la parte exterior del ala del perfil metálico a proteger con clavos de acero cada 725 mm como máximo.

Fijar el perfil angular30x30x0,6 mm sobre las tiras de Paneles Tecbor® y estos sobre las omegas, mediante tornillos autorroscantes cada 250 mm. Ensamblar las tiras..

Aplicar Pasta de juntas Tecbor® en las cabezas de los tornillos y en la junta entre placas.

NOTA: En el caso de que la protección se realice con paneles Tecbor® de espesor igual o superior a 30 mm, es posible atornillar panel con panel a hueso con tornillo 5 x 80 mm cada 250 mm.

| TEST

Standard :UNE ENV 13381-4 |

SOLUTION

1. Tecbor® Boards. |

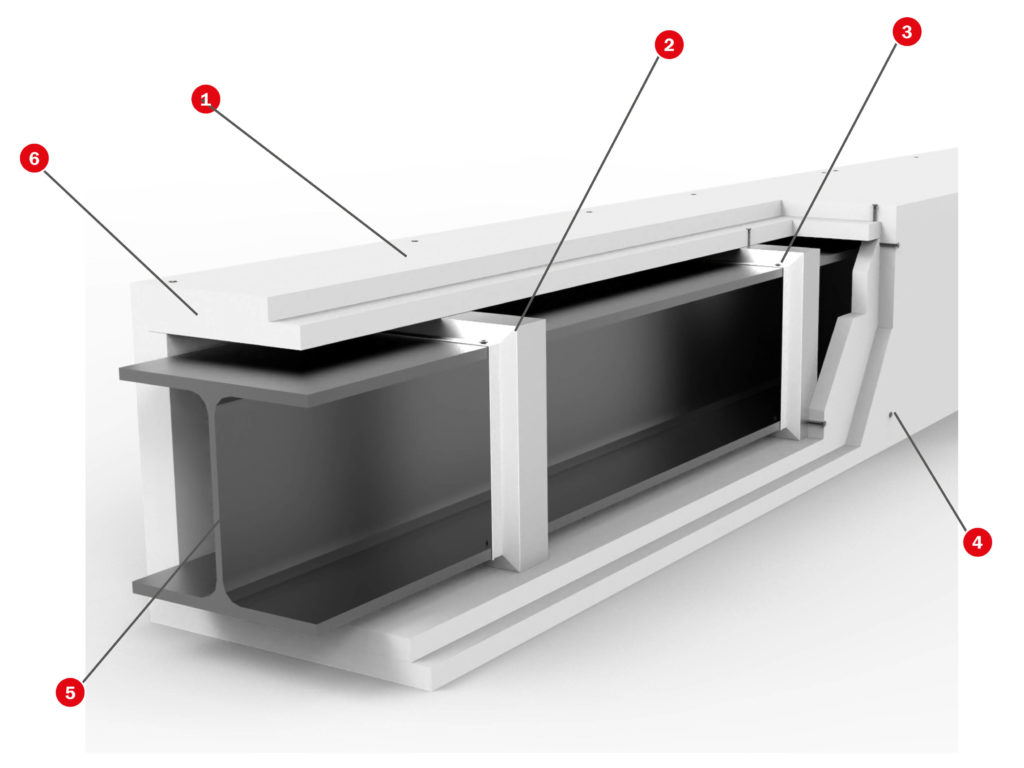

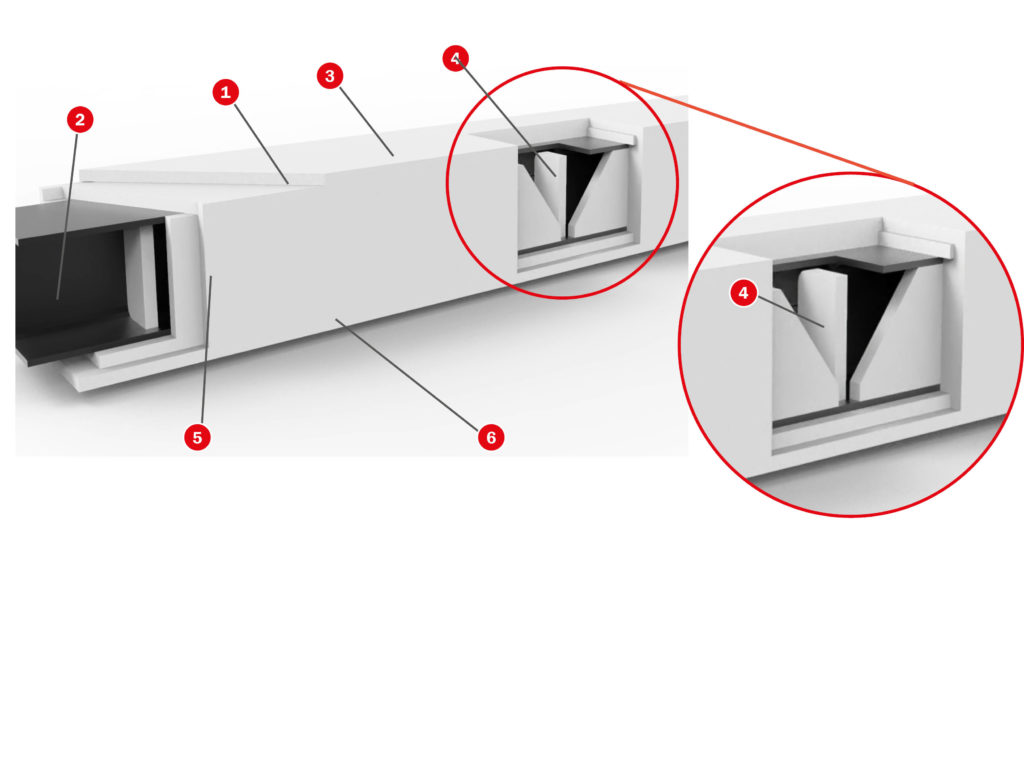

Description of Assembly

Cut support stiffeners with Tecbor® boards of 20 mm, of 100 mm in width and adapted to the measurements of the metal profile to be protected. Insert them using a wedge as indicated in the detailed plans at intervals of no more than 600 mm.

Attach the Tecbor® side plates to the support stiffeners so that the joints between the plates overlap on a support stiffener. These Tecbor® side plates will be attached using metal brackets separated at intervals of 50 mm between plates.

A support stiffener will only be attached to the Tecbor® side plates for the beams, using metal brackets, on the lower face of the profile to be protected and formed with Tecbor® boards of 20 mm and 100 mm in width.

Attach the lower Tecbor® boards to the side ones and to the lower support stiffeners using metal brackets separated at intervals of no more than 100 mm.

Brackets of a length that is equal to or greater than the total thickness of the plates to be joined will be used; their minimum dimensions will be 35 x 10.6 x 1.6 mm.

Do you have any questions about the product?

Learn More About

Steelwork Protection with: