Tecbor® Boards - Constructive Solutions

Tecbor® Boards - Non-Structural Elements - Walls

Non-structural walls, which separate fi re areas, should be fire resistant as stipulated in standard EN 1364-1.

When in fire resistance tests for non-structural elements one edge is left free (Part 1: Walls), the standard allows increasing the width.

With regard to increasing the height, the standard is clear and precise. When the test is run at least at 3 metres high, it may be increased up to 4 metres.

Very often, internal partitions are higher than 4 metres. mercor tecresa® have been the first to develop large partitions and offers the most efficient and convenient solution for this type of works.

Besides, penetrations produced between different fire sectors must be sealed off; for example, in the case of services crossing. Check the TECSEL® Sealing System catalogue to find the most suitable solution.

| TEST

Standard : UNE EN 1364-1 |

SOLUTION

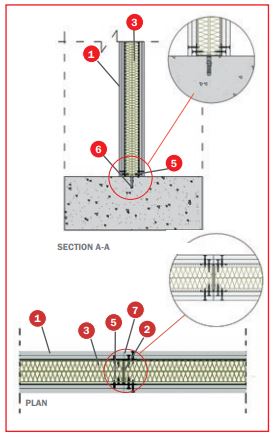

1. Tecbor® A 15 mm. boards. 5. 83 x 40 x 0,6 mm runner. 8. Tecbor® bonding compound. (on every joint and over the screw heads). |

Description of Assembly

Fix 83x40x0,65 mm runners and assembly the 34,8 x 40 x 0,6 mm studs every 600 mm. Place 80 mm (40+40) and 40 Kg/m3 rock wool panels between studs.

Then fix Tecbor® 15 mm boards to both sides with 3,5×35 mm self-tapping screws every 250 mm.

Finally, cover board joints and screw heads with Tecbor® joint paste or Tecbor® bonding compound.

Product document

Description of Assembly

Attach 73x30x0.5 mm runners and assemble 70x36x0.6 mm studs every 610 mm. Fill in frame with 60 mm (30+30 mm) and 100 kg/m3 rock wool panels.

Attach both Tecbor® A 12 mm board layers with 3.5×35 mm selftapping screws every 200-250 mm alternating the layers.

Use Tecbor® joint paste in screw heads and between boards.

Upon running the test, a 0.6 mm thick galvanised sheet was mounted on the unexposed surface, fixed to the studs with 13 mm sheet-metal screws. This sheet is not fire resistant; therefore, it can be replaced in the final assembly.

An IPN 140 metal profile was placed in the test furnace frame centre.

Product document

| TEST

Standard : UNE EN 1364-1 |

SOLUTION

1. Tecbor® 10 mm boards. |

Description of Assembly

Attach 73x30x0.5 mm runners and assemble 70x36x0.6 mm studs every 610 mm. Fill in frame with 60 mm (30+30 mm) and 100 kg/m3 rock wool panels.

Attach both Tecbor® A 15 mm board layers with 3.5×35 mm self-tapping screws every 200-250 mm alternating the layers.

Use Tecbor® joint paste in screw heads and between boards.

Upon running the test, a 0.6 mm thick galvanised sheet was mounted on the unexposed surface, fixed to the studs with 13 mm sheet-metal screws. This sheet is not fire resistant; therefore, it can be replaced in the final assembly.

An IPN 140 metal profile was placed in the test furnace frame centre.

Product document

| TEST

Standard : UNE EN 1364-1 |

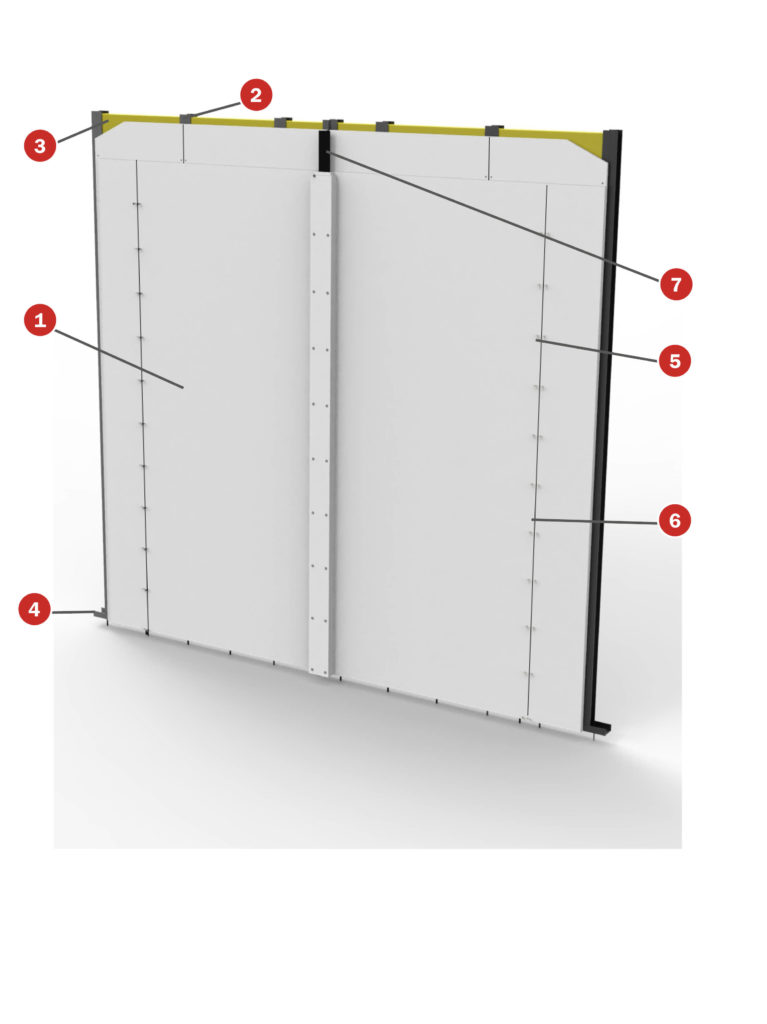

SOLUTION

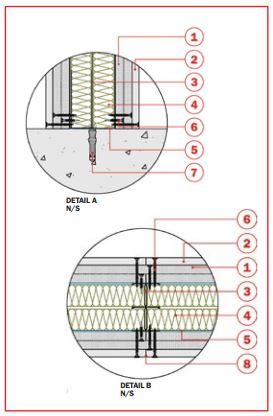

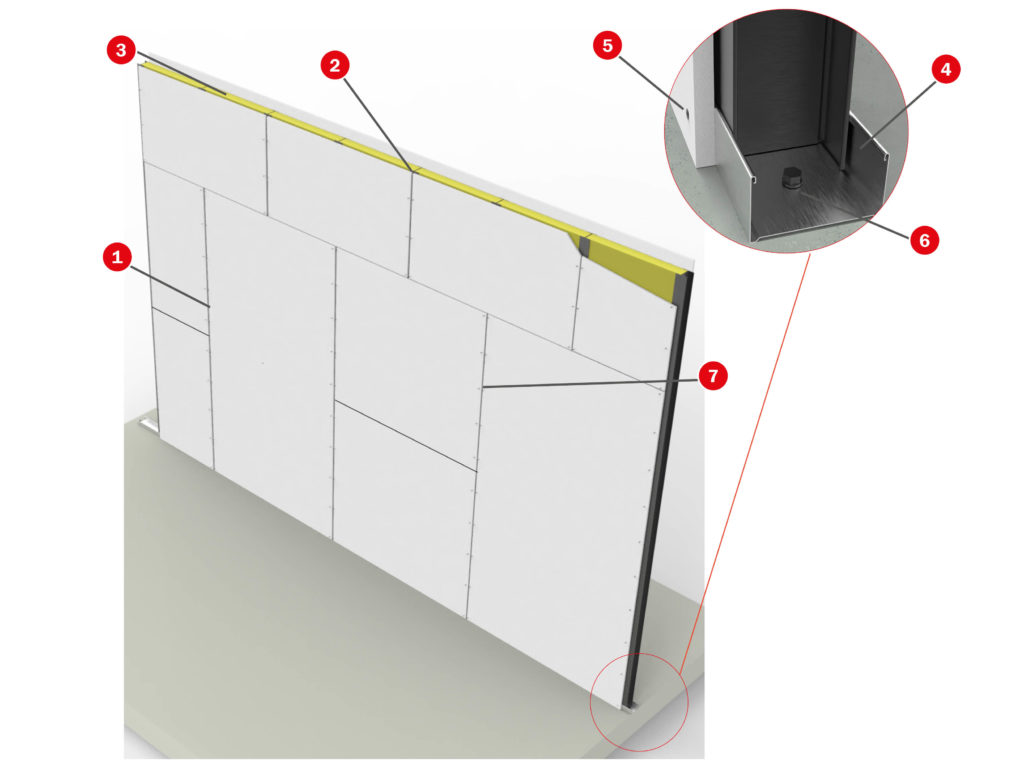

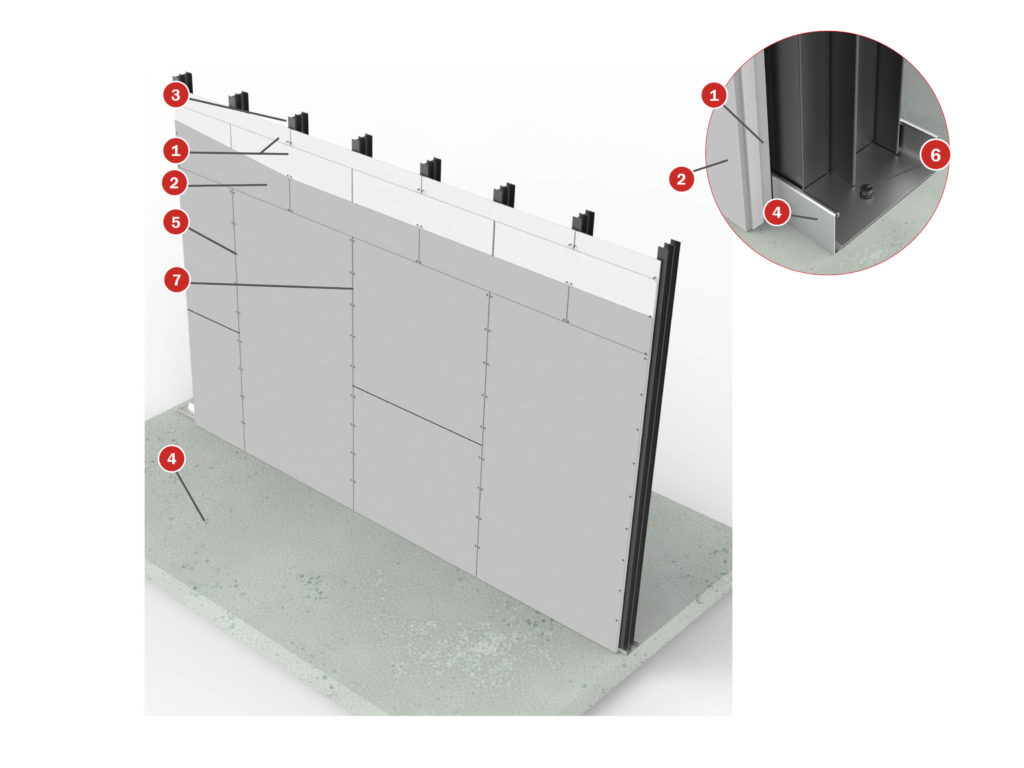

1. Tecbor® 15 mm boards. 7. Punch-activated drop-in 6 mm anchor, every 600 mm. |

Description of Assembly

Attach 48×0,6 mm runners and assemble 46×0,6 mm studs every 600 mm. Place 80 mm (40+40) and 40 Kg/m3 rock wool panels between studs.

The fix Tecbor® 15 mm boards to both sides with 3,5×35 mm self-tapping screws every 250 mm.

Finally, cover board joints and screw heads with Tecbor® joint paste or Tecbor® Bonding Compound.

Product document

| TEST

Standard : UNE EN 1364-1 |

SOLUTION

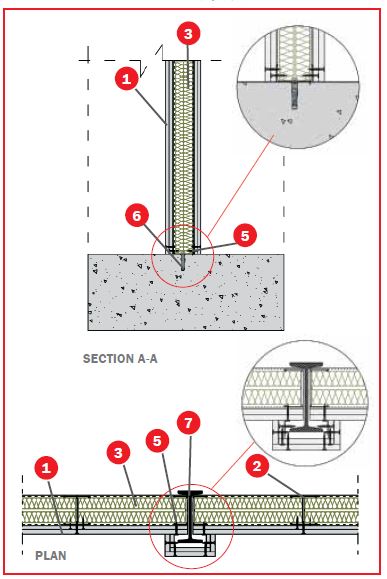

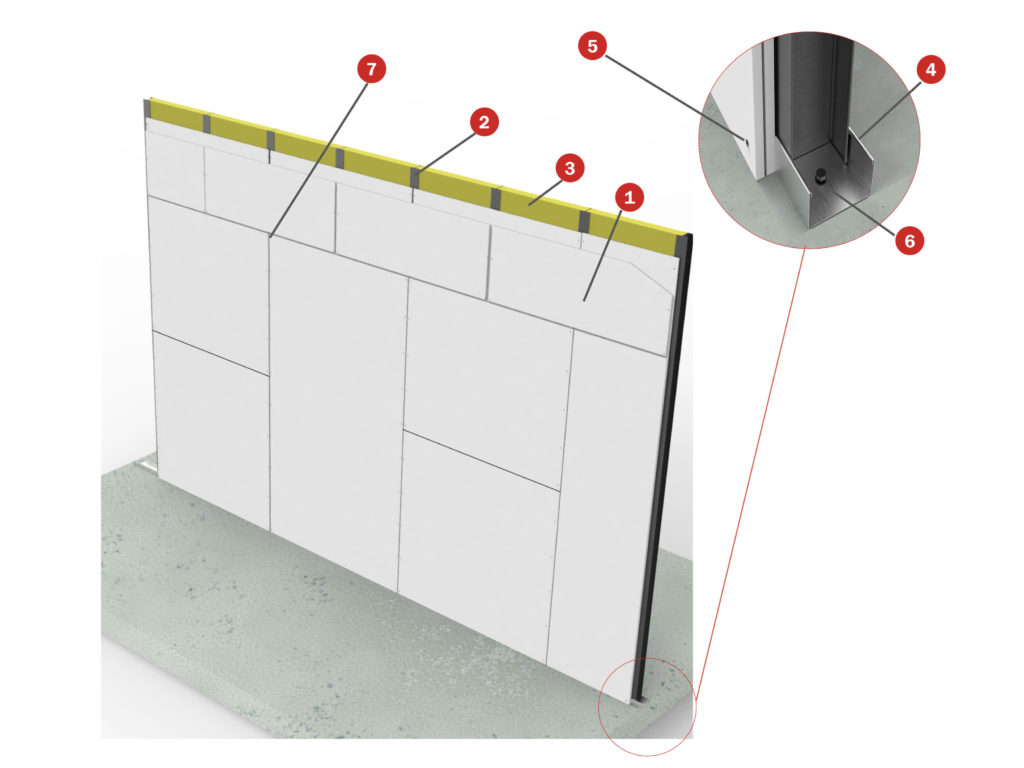

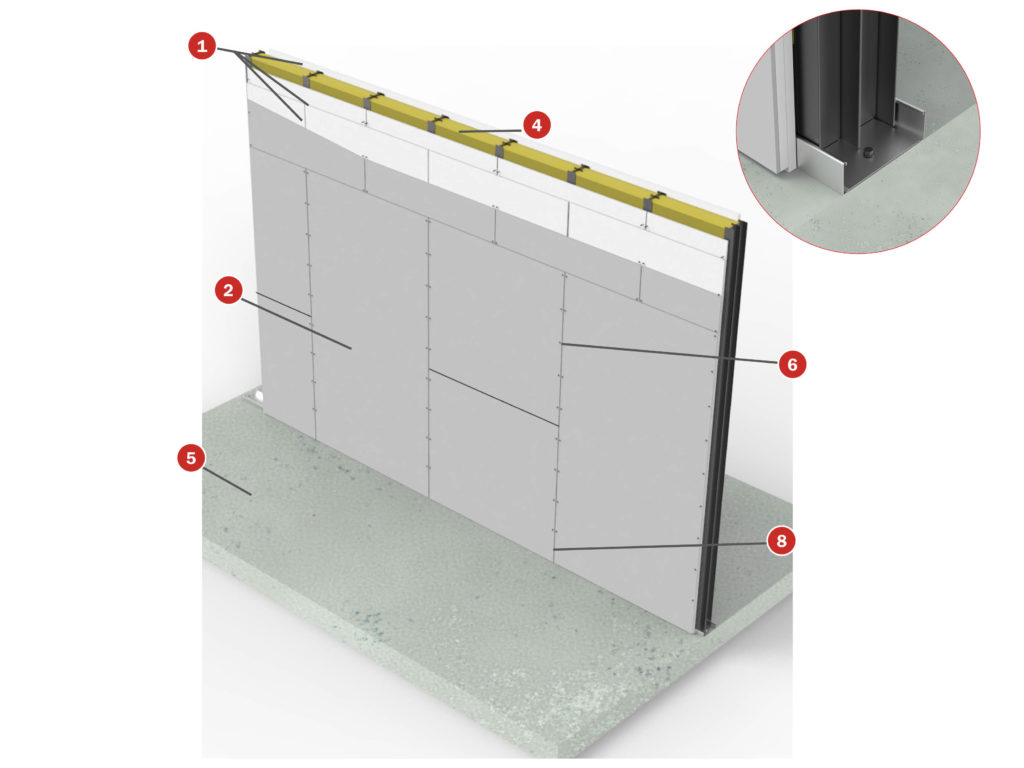

1. Tecbor® 12 mm boards. 6.Tecbor® joint paste or Tecbor® bonding compound. 9. M6 metal plug. |

Description of Assembly

Attach 73x30x0.5 mm runners and assemble 70x36x0.6 mm studs every 610 mm. Fill in frame with 80 mm (40+40 mm) and 40 kg/m3 rock wool panels.

Attach both Tecbor® 12 mm board layers with 3.5×35 mm self-tapping screws every 200-250 mm alternating the layers.

Use Tecbor® joint paste in screw heads and between boards.

Finally, cover board joints and screw heads with Tecbor® joint paste or Tecbor® Bonding Compound.

Product document

| TEST

Standard : UNE EN 1364-1 |

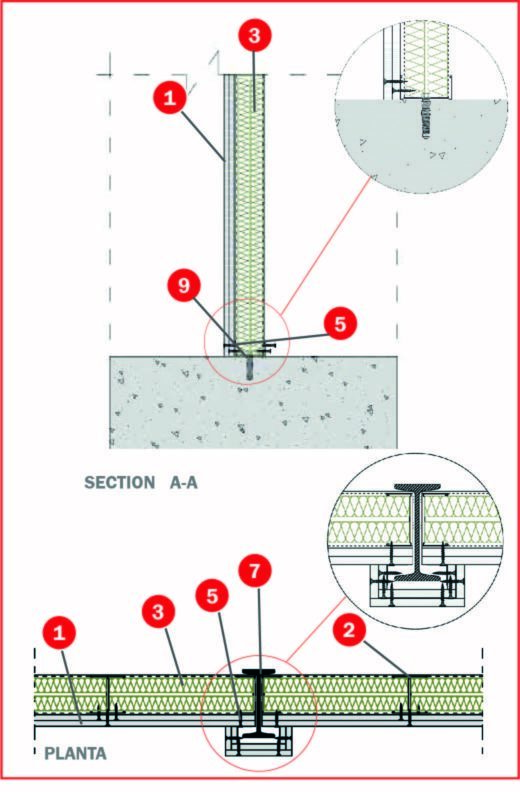

SOLUTION

1. Tecbor® 15 mm boards. 6. Punch-activated drop.in 6 mm anchor, every 600 mm. |

Description of Assembly

Attach 83 x 40 x 0,65 mm runners and assemble the 34,8 x 40 x 0,6 mm studs every 600 mm.

Then fix Tecbor® 15 mm boards to both sides with 3,5×35 mm self-tapping screws every 250 mm.

Finally, cover board joints and screw heads with Tecbor® joint paste or Tecbor® bonding compound.

Product document

Do you have any questions about the product?

Learn More About

Partition wall/large format cladding with: