Tecbor® Boards - Constructive Solutions

Tecbor® Boards - Suspended Ceilings and Slabs Protection

Fireproof suspended ceilings are used mainly in two specific cases:

- The first case is to isolte different fire sectors vertically. This action helps restrain fire to its starting point and avoids its propagation to other areas. This solution is highly useful in the case of hihg-rises since partial sector division might cause the fire to spread easily causing serious problems during evacuation.

- The second case is to protect the various objects found above the ceiling; for example, installations, structures, slabs, etc.

According to our requirements, we shall use either application. Our solutions have been tested when fire strikes from below.

| TEST

Standard: UNE EN 1364-2 |

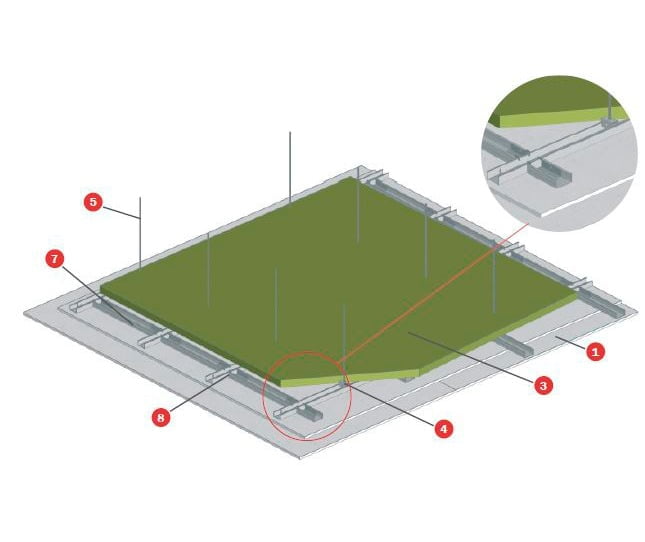

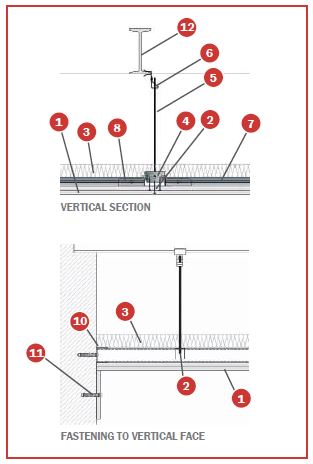

SOLUTION

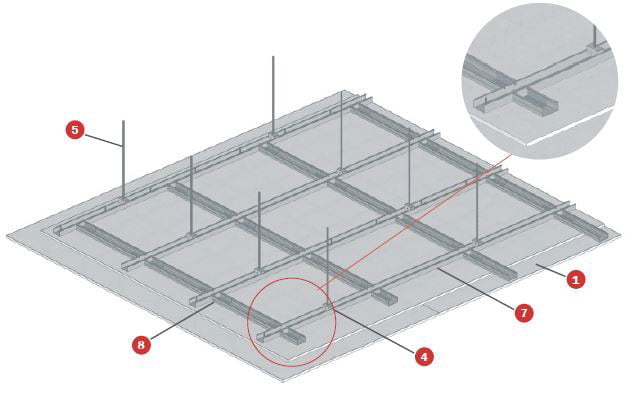

1. Tecbor® 12 mm boards. 7. TC 60/27.

|

Description of Assembly

Fix 48x30x0.5 mm runners with 10×100 mm plugs every 500 mm approximately around the ceiling’s perimeter.

Then install TC 60/27 profiles at a distance of 610 mm between axes placing such sections crosswise through a steel grip for TC 60/27 forming 610×610 mm frames. Using the steel grips, the M6 rod and the clamps, fix the structure to the one supporting the ceiling.

Once the metal structure is finished, fix the first Tecbor® 12 mm boards to the first layer alternating it with the 40 mm and 40 kg/m3 rock wool above the structure. Then, place the second board layer using 3.5×45 mm self-tapping screws alternating it with the first layer.

Use Tecbor® 12 mm to finish off the assembly witha 150 mm wide base-board.

Distance between screws will be approximately 250-300 mm.

Screw heads and inter-board joints will be covered with Tecbor® joint paste.

Product document

| TEST

Standard: UNE EN 1365-2 |

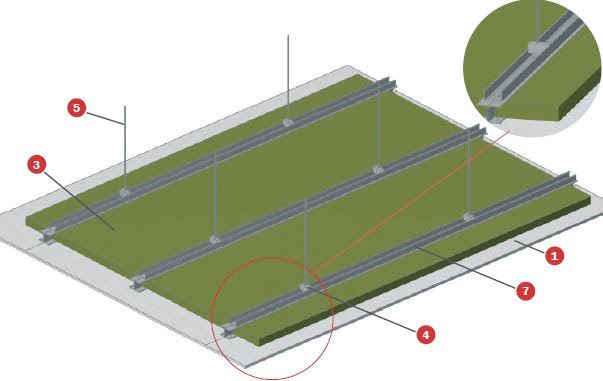

SOLUTION

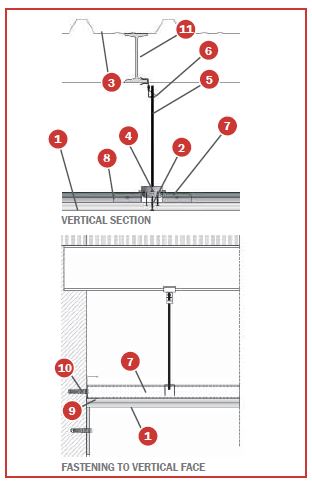

1. Tecbor® 12 mm boards. 7. TC 60/27. |

Description of Assembly

Fix 48x30x0.5 mm runners with 10×100 mm plugs every 500 mm approximately around the ceiling’s perimeter. Next place profiles made up of 246x36x0.6 mm studs arranged in “H” position lying down. Put the rock wool panels in between. Studs are fixed to TC 60/27 profiles by the upper part and suspended from the slabs through a hanging system including a Steel grip, an M6 rod and clamps every 600 mm approximately. Inter-section joints are connected through 2.9×13 mm metal/metal selfdrilling screws.

Then Tecbor® 12 mm boards are fixed using 3.5×35 mm screws every 250-300 mm. The work is completed with a 150 mm baseboard of Tecbor® 12 mm placed all around the perimeter.

Distance between screws will be approximately 250-300 mm.

Screw heads and inter-board joints will be covered with Tecbor® joint paste.

On top of the suspended ceiling and the IPE 140 metal profiles a 0.6 mm thick ribbed sheet was placed at 400 mm.

Product document

| TEST

Norma: UNE EN 1365-2 |

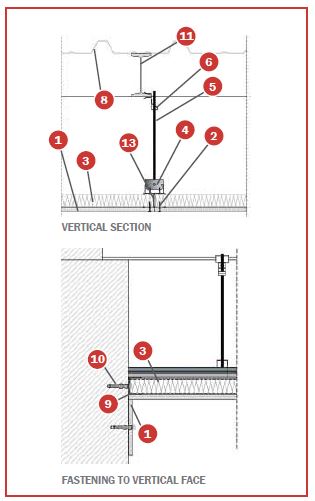

SOLUTION

1. Tecbor® 12 mm boards. 7. TC 60/27. |

Description of Assembly

Fix 73x30x0.5 mm runners with 10×100 mm plugs every 500 mm approximately around the ceiling’s perimeter. Then install TC 60/27 profiles at a distance of 610 mm between axes placing such sections crosswise through a Steel grip for TC 60/27 forming 610×610 mm frames. Using the steel grip, the M6 rod and the clamps, fix the structure to the one supporting the ceiling.

Attach both Tecbor® 12 mm board layers with 3.5×45 mm self-tapping screws. Then alternate the second Tecbor® board with the first one.

Use Tecbor® 12 mm to finish off the assembly with a 150 mm wide base-board around the perimeter.

Distance between screws will be approximately 250-300 mm. Screw heads and inter-board joints will be covered with Tecbor® joint paste.

On top of the suspended ceiling and the IPE 160 metal profiles a 0.6 mm thick ribbed sheet was placed at 550 mm.

Product document

| TEST

Standard: UNE EN 1365-2 |

SOLUTION

1. Tecbor® 15 mm boards. 7. TC 60/27. |

Description of Assembly

Fix 73x30x0.5 mm runners with 10×100 mm plugs every 500 mm approximately around the ceiling’s perimeter. Then install TC 60/27 profiles at a distance of 610 mm between axes placing such sections crosswise through a Steel grip for TC 60/27 forming 610×610 mm frames. Using the steel grip,

the M6 rod and the clamps, fix the structure to the one supporting the ceiling.

Attach both Tecbor® 15 mm board layers with 3.5×45 mm selftapping screws. Then alternate the second Tecbor® board with the first one.

Use Tecbor® 15 mm to finish off the assembly with a 150 mm wide base-board around the perimeter.

Distance between screws will be approximately 250-300 mm. Screw heads and inter-board joints will be covered with Tecbor® joint paste.

On top of the suspended ceiling and the IPE 160 metal profiles a 0.6 mm thick ribbed sheet was placed at 550 mm.