Tecbor® Boards - Curtain Walls

The DB SI in its section concerning external propagation, indicates that in order to limitate the risk of vertical propagation through the façade between two fire sectors, between a particularly high risk area and other higher zones

in the building, or towards a protected staircase or protected corridor, this façade shall be at least EI-60 in a belt with height of not less than 1 metre.

Catastrophes affecting high-rises have shown the importance of protecting and anchoring joints between both slabs and facades. Otherwise, existing holes between curtain walls and light facades can work as true chimneys in case of fire causing flames and smoke to get out of control propagating into higher areas in the building, and thus hampering an orderly evacuation procedure.

The manifold and various configurations of facades make it difficult to decide on the most appropriate protection. Therefore, do not hesitate to contact our Sales Department for assistance.

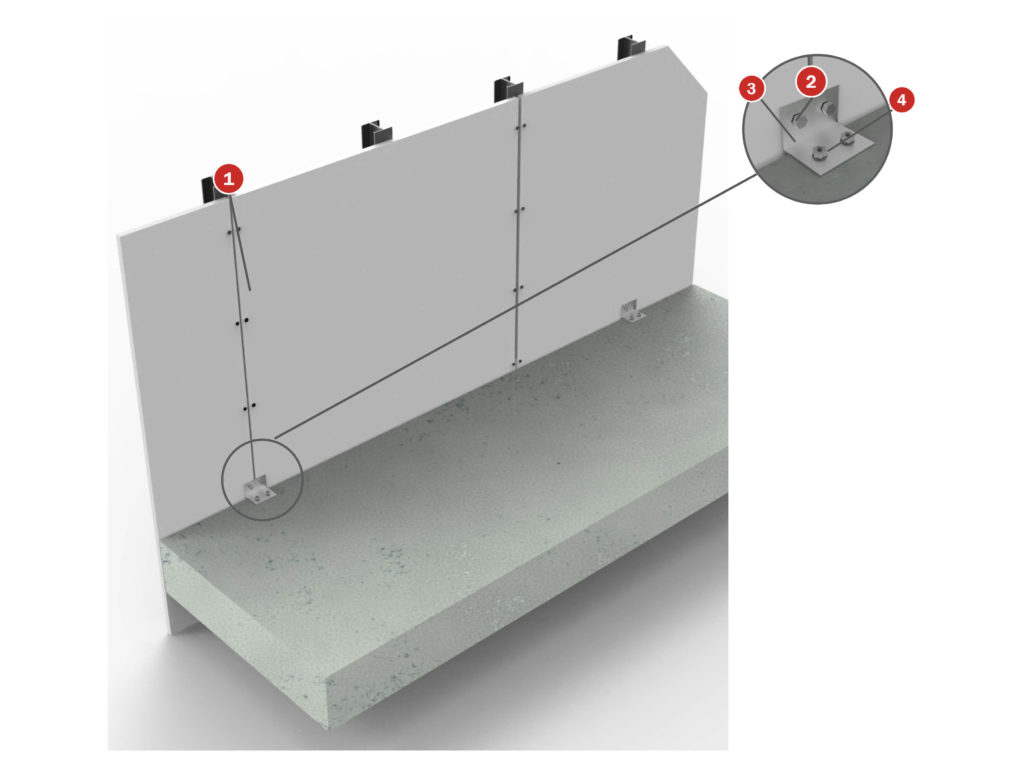

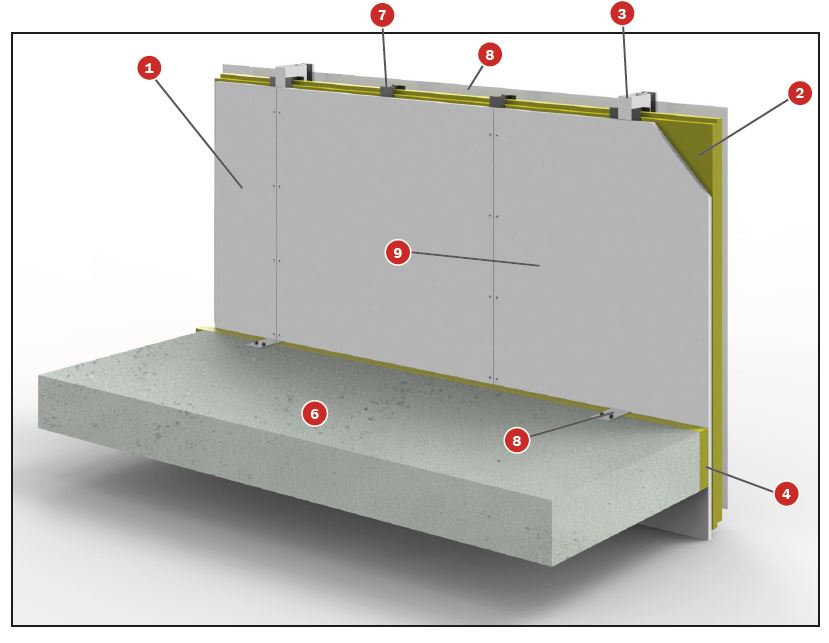

Description of Assembly

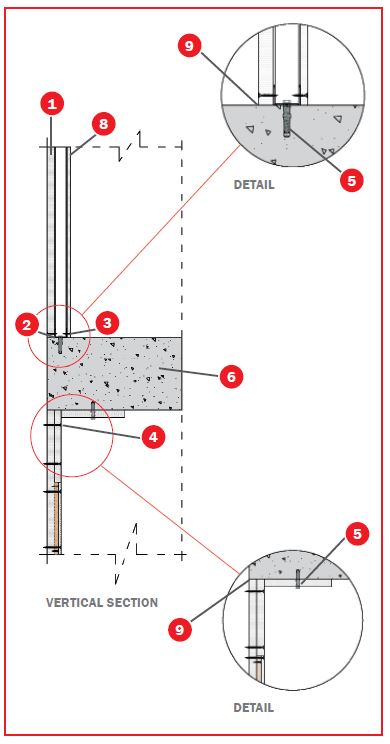

Fix the 40x40x2 mm supporting metal angle to the Tecbor® 30 mm board using fixing anchors every 500 mm.

Once the angles are fixed to the boards, fix to the slab using M6 metal plugs. Then place Tecbor® 30 mm plates 250 mm wide using 3,5×45 mm screws.

Then Tecbor® Joint Paste or Tecbor® bonding compound is applied to all screw heads and between boards.

Product document

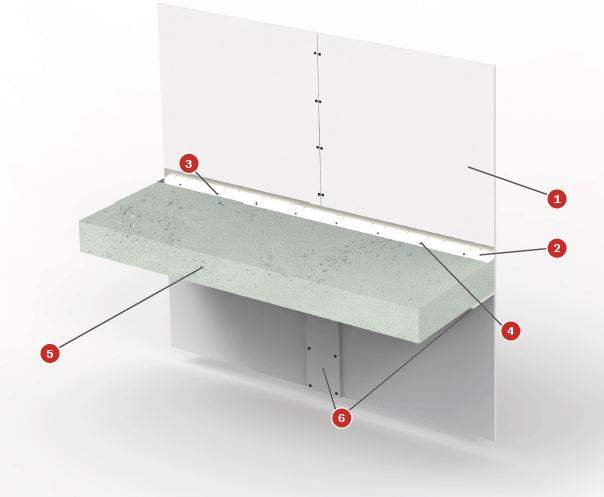

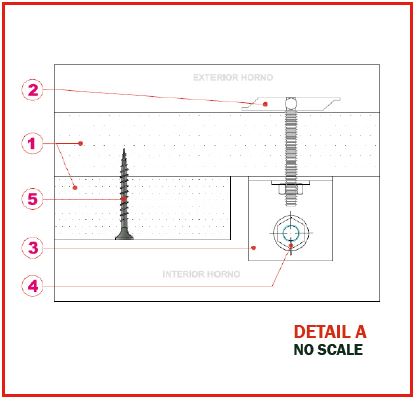

Description of Assembly

Fix the 70x70x1 mm L-shaped profile to the Tecbor® 20 mm board by using 3,5×45 mm Self-tapping screws every 250-300 mm approximatively. Fix the other part of the L-shaped profile to the slab by using a 10×100 mm stud anchor every 250-300mm approximatively.

Then fix a 20 mm Tecbor® strip, 200-250 mm wide, on the bottom part of the slab by using a 10×100 mm stud anchor.

Place the 20 mm Tecbor® strips, 200-250 mm wide, on the joints of the bottom part of the curtain wall by using 3,5×45 mm Selftapping screws.

Finally, apply Tecbor® Joint paste on all the joints between boards and on the heads of the screws.

Product document

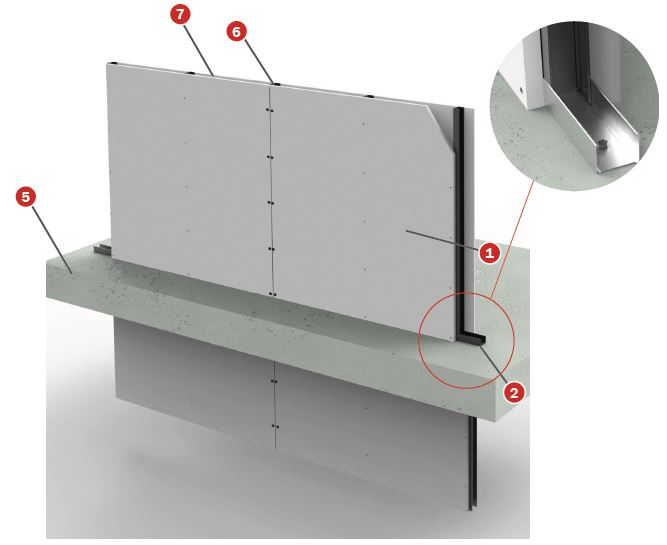

Description of Assembly

Fix a 48x30x0.5 mm metal runner to the slab by using a 10×60 mm stud anchor. Place the 46x36x06 mm frames with a distance of 610 mm between the axes. Then fix the Tecbor® 20 mm boards to the structure by using 3,5×35 mm screws.

Apply Tecbor® Joint paste on all the joints between boards and on the heads of the screws.

Finally, fix a 13 mm plasterboard panel inside the solution by using 3,5×35 mm self-tapping screws.

Product document

| TEST

Standard : UNE EN 1364-1 |

SOLUTION

1. Tecbor® B 20 mm boards. |

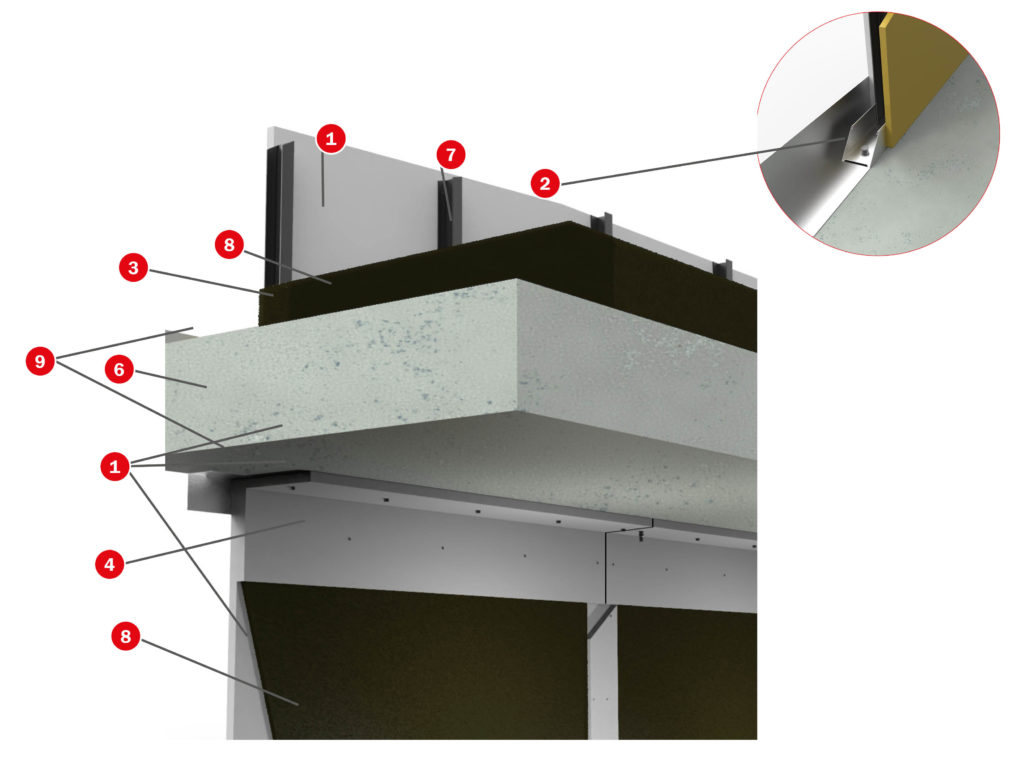

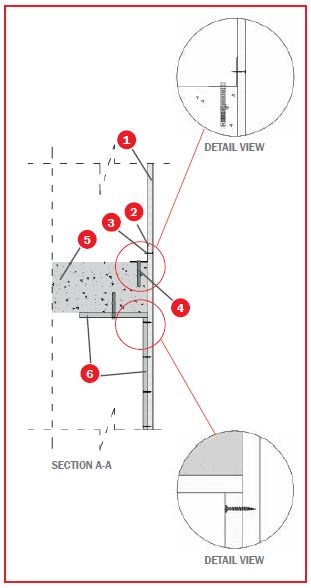

Description of Assembly

This is a curtain wall solution without assymetrical crossing slab. The upper side, is a partition without wool.

It consists in a 13 mm laminated plaster partition fixed on the inner side to a 46 mm metal stud by means of 3.5 x 35 mm dry partition hardware. On the opposite side, it has a 20 mm Tecbor® board fixed to the 46 metal stud by means of 3.5 x 35 mm dry partition hardware.

On the slab lower part, Tecbor® boards were installed with 70 x 70 x 1 mm angle and 3.5 x 45 mm screw.

Product document

| TEST

Standard : UNE EN 1364-4 |

SOLUTION

1. 10 mm Tecbor® 20 mm boards. |

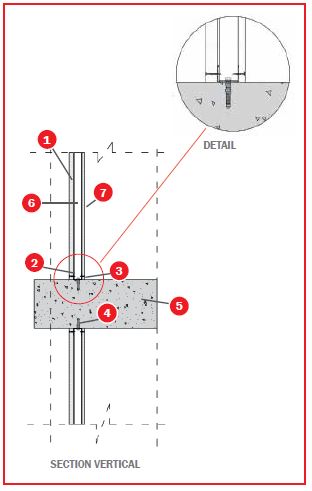

Description of Assembly

This solution is an asymmetrical curtain wall without crossing the slab. The upper side is a partition without wool.

It consists in a 13 mm laminated plaster partition, without wool, fixed on the inner side to a 46 mm metal stud by using a 3.5 x 35 mm screw. The opposite side has a 10 mm Tecbor® board fixed to the 46 metal stud by using 3.5 x

35 mm screws.

On the lower part of the slab, Tecbor® boards are installed with a 70 x 70 x 1 mm L-shaped profile and a 3.5 x 45 mm screw.