Tecbor® Boards - Ventilation & smoke extraction ducts

The regulatory requirements demand the compartment of elements when traversed by installations, such as pipes or extraction and ventilation ducts.

- Fire resistance required to the fire compartment elements must be kept on the points where such elements are traversed by installation materials, such as cables, pipes, ducts, ventilation ducts, etc. To that end, a choice can be made between the following alternatives:

- Put an element which, in case of a fire, automatically blocks the cross section and guarantees in such point a fire resistance at least equal to that of the traversed element, for example, an automatic firewall dumper. The t (i↔o) being the fire resistance time required to the traversed compartment element, or a blocking intumescent device.

- Crossing elements which provide a resistance at least equal to that of the traversed element, for example, EI ventilation ducts t (i↔o)

being t the fire resistance time required to the traversed compartment element

From the previous paragraph follows that the fire resistant ducts which pass through fire compartments must have the compartments from within and from the outside to it.

RSCIEI describes in its annex II Article 5.7:

“Systems including ducts, both verticals and horizontal, which traverse compartment elements and whose function doesn’t allow the use of dampers (smoke exhaust, ventilation of evacuation routes, etc.), must be fire resistant or adequately protected throughout its route with the same level of fire resistance than the traversed elements, and tested according to the applicable UNE-EN

standards”.

UNE EN applicable standards, as they appear in Annex DB SI G of the TBC are:

- UNE EN 1366 Part 1 for ventilation ducts.

- UNE EN 1366 Part 8 for multi-sector extraction ducts.

Ventilation duct Type A,B & C. Tecbor® 30 EI-120

| TEST

Standard : UNE EN 1366-1 |

SOLUTION

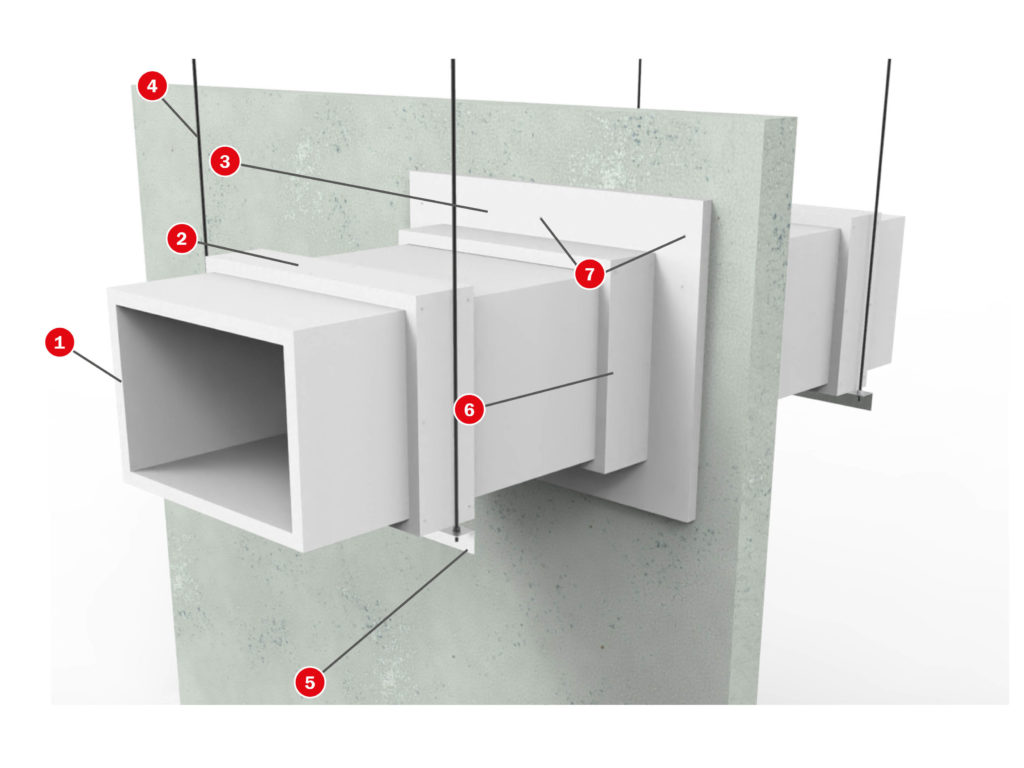

1. Tecbor® 30 mm. boards. |

Description of Assembly

Duct composition:

Duct consisting of Tecbor® boards 30 mm thick.

Fixings between sections:

Longitudinally, the boards are joined with Tecsel® adhesive.

Transversally, duct sections are joined with perimeter joint covers formed by Tecbor® boards of 30 mm thick and 250 mm wide.

The joint covers are fixed to the section with 2 lines of 5 x 60 mm threaded wood screws, screwed every 250 mm on the long sides and 200 mm on the short ones. Lines distanced between each other 160 mm.

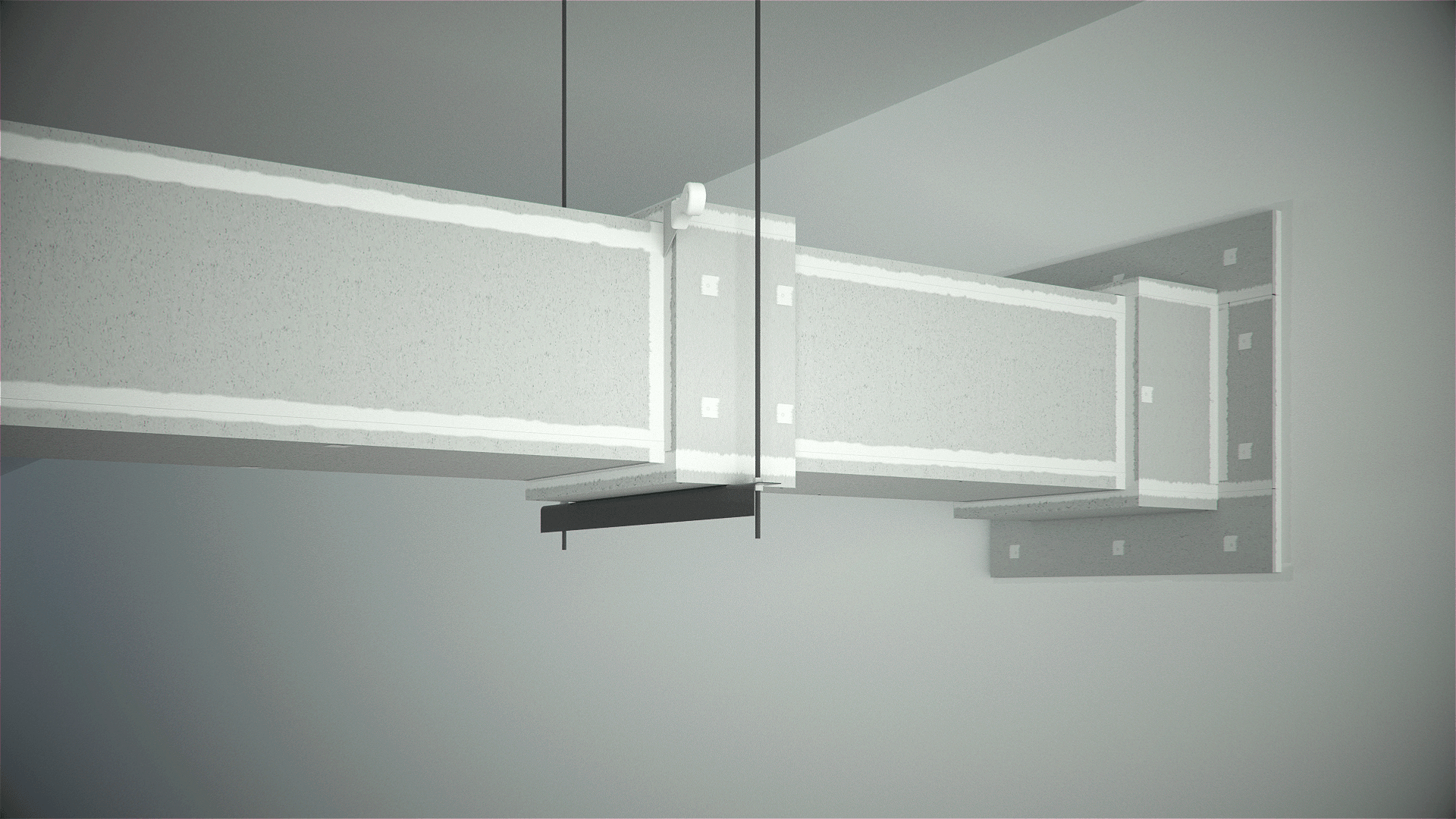

Duct support method:

The duct is supported by an auxiliary structure made up of M16 threaded rods and 50 mm x 50 mm and 5 mm thick L-shaped upon which the duct rests. Maximum distance between the hangs will be 1200 mm.

Sealing of the penetration point through the support work. Sealing will be carried out with the following elements:

- Tecbor® boards 30 mm thick.

- Rock wool 50 mm thick and density 145 Kg/m3.