Manual for the protection against fire of load bearing structures “wooden structures” (Part 3)

Contrary to what one might think, wooden structures have a few advantages compared to other materials like concrete or steel:

- They stand higher temperatures, without important dilatations nor changes in their internal composition.

- When they start burning, it is possible to calculate their section loss and the moment that they will collapse, unlike concrete and steel that have unpredictable behaviours.

This predictable and constant behaviour of the wood in contact with fire gives us two possible solutions to protect it:

1.- Increase its section according to its carbonation speed for it to maintain its minimum efficient section in case of fire and remain capable of bearing the load applied to it.

In order to do so, we need to calculate the moment when the structural element is going to collapse according to its section loss speed by carbonation.

We need to refer to the combustion temperature of the wood, the temperature to which it starts burning and carbonating. This temperature depends on lots of factors like density, humidity, wood type, etc. But we will generally consider a temperature of 230ºC.

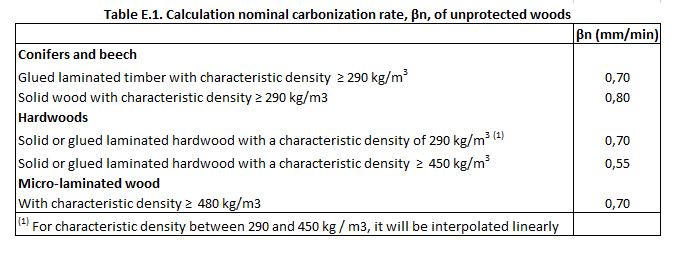

The Technical Building Code gives us the following indications regarding the different types of wood:

Generally, we will consider the need to reinforce the structure so it can face a section loss speed of 0,7mm per minute. To increase its section, only the faces exposed to fire need to be considered.

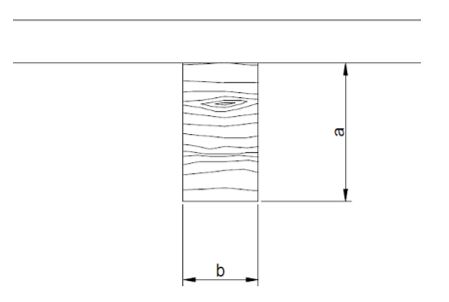

For the example of a wooden beam exposed to fire on three faces, we first calculate the minimum section it needs to bear the load applied to it, then we calculate the additional section needed in order to resist the fire for the required amount of time according to its carbonation speed.

The minimum section would be a x b, but for the beam to be R-60 with a speed of 0,7mm/minute, it needs a section of (a+42 mm) x (42+b+42 mm). As for a pillar with the same section with all four faces exposed to fire, we will need a section of (42+a+42 mm) x (42+b+42 mm).

2.- Use of protection layers: when the oversizing protection is not possible, we have no choice but to protect the structure with a product or a solution that reinforces its resistance to fire. The Research and Development Department of Mercor Tecresa has developed two types of solution:

-

- Tecbor Panels made of Magnesium Oxide and Silicate: These panels have been tested as false ceiling (beam protection) and as partition walls (pillar protection) to ensure the insulation and integrity of the wooden structure. The tests show that the panels prevent the temperature to go over 140ºC, and as we have seen earlier, the wood only starts its carbonation when reaching 200ºC. The load bearing capacity of the wood stays intact during the fire, preventing the protected structure from collapsing.

- Tecwool Mortar: This is the most common solution because of its attractive price. However, unlike Tecbor panels that are already smooth and can immediately be painted on, the mortar often requires a posterior finish. The Tecwool mortar has been tested for the protection of ceilings supported by wooden beams with a minimum section of 140 x 140 mm to guarantee 3 hours (180 minutes) of load bearing capacity once the fire starts.

It is very common, especially with renovation works, to find wooden or concrete structures with metallic reinforcements. Those reinforcements handle on their own the entire load bearing capacity of the structure. In this case, the structural element will be treated as a metallic structure (see previous post).