Manual for the protection against fire of load bearing structures (metallic structures)

Actualizado a fecha: 14 October, 2021

After concrete structures, let us now talk about metallic load bearing structures, particularly sensitive to high temperature in case of fire. Above 500ºC, the metal deforms and loses its load-bearing capacity, leading to the collapse of the structure. This is why it is necessary to protect metallic structures by making sure they don’t reach their critical temperature.

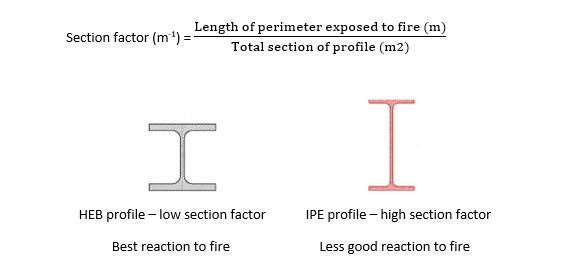

All metallic profiles don’t behave the same when facing a fire. The thicker the profile, the best it will react. On the contrary, the thinner the profile and the bigger the exposed surface, the worst it will react. To quantify the good or bad behaviour of a profile, it is necessary to calculate its SECTION FACTOR. This is the relationship between the face exposed to fire and the total volume of the metal profile. For standard section profiles we can substitute this formula by the coefficient between the length of the perimeter of the profile divided by the area of its cross-section, all in meters

Between the obtained value, the fire resistance time required by the regulations, and the critical temperature of the metal, we can calculate the thickness of material required by referring to the results of standard fire protection tests for metal structures. The European standard that governs these tests is UNE ENV 13381-4.

At mercor tecresa® we have developed and tested according to the current regulation four different products that will be used according to the fire resistance and finish required:

- Tecwool® F Mortar: It´s a mortar composed of rock wool, white cement, and other additives, which is applied to metal profiles through pneumatic projection. Its normal appearance is rough, and it has the advantage of absorbing the movements of the metal structure without cracking and breaking.

- Tecplaster® Mortar: It´s a mortar composed of perlite and vermiculite, and plaster that acts as a binding agent. It is applied with a mortar or plaster spraying machine. Its normal appearance is rough, and its main advantage is its great hardness once it is dry.

- Teclack-W® Paint: It is a water-based intumescent product that is applied using an airless gun, brush, or roller. Its reaction when entering in contact with fire lowers the temperature and generates ash that thermally isolates the metal profile. The finish depends on the thickness, and the appearance will be rougher by increasing it. This solution is optimal when the required fire resistance is 15-30 minutes. It has a beautiful finish at a reasonable price.

- Tecbor® Panels: It´s a rigid panel of high flame retardant performance, composed of silicates and magnesite. It is installed using a laminated plasterboard type frame or with clips, surrounding the profile we want to protect. Its great advantage is its elegant finish, and it is ideal when we want to protect a reduced number of profiles or when the thickness of protection to be applied must be thin.

For example: to protect a metal beam IPN 260 against fire…

- The Construction Management gives us the requirements of the regulations, for example a critical temperature of 550ºC and a fire resistance of 120 minutes.

- Calculate the section factor of the beam

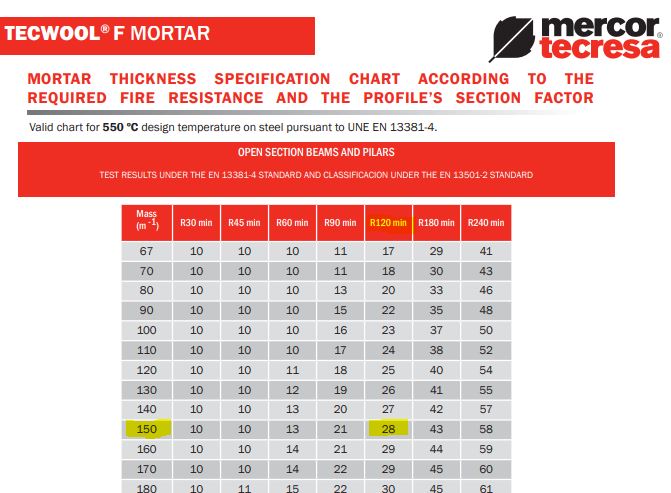

- We then need to choose the product we want to use for fire protection between the fire protection mortar, the intumescent paint, or the rigid fireproof panels. In this case, let’s choose Tecwool F mortar. For fire exposure on 3 faces and applying the mortar to the contour of the profile, the table gives us a section factor of 148.5 m-1.

- Finally, let us go to our website to see the test tables for the desired product:

- Acudimos a la Web del fabricante, en este caso mercor tecresa® y vamos a las tablas de ensayo para ese producto (Tabla de espesor Mortero Tecwool F).Y nos aparece la siguiente tabla para 500 ºC

We can see that for the Section Factor and fire resistance required, the thickness to be applied is 28 mm.

|

¿TIENES ALGUNA DUDA? ¡ Póngase en contacto con nuestro departamento técnico ahora! |

We can see that for the Section Factor and fire resistance required, the thickness to be applied is 28 mm.

We can see that for the Section Factor and fire resistance required, the thickness to be applied is 28 mm.