Fire Dampers: EIS-120 rectangular dampers

For a long time now, ventilation and air conditioning of buildings have been carried out through ducts. In addition, according to the new certifications (Passivhaus, Leed, Breeam, Verde, etc.), this kind of ducts is essential to achieve a correct ventilation and save energy more efficiently.

Ducts that run through several rooms and fire areas have often been responsible for fire spreading within buildings. Therefore, various fire safety standards require the installation of solutions that will prevent the fire from spreading. The regulations vary from country to country, but it is common to meet the following requirements:

The fire resistance required for fire compartmentalization elements must be maintained at all points, including places crossed by installations, such as cables, pipes, ventilation ducts, etc. There are two options to do so:

(a) Install an element which, in case of fire, automatically obstructs the passage section and ensures at that point a fire resistance at least equal to the one of the element crossed, e.g., a fire damper EI t (i <->o), t being the required resistance time for the crossed element.

(b) Install passing elements that provide a resistance at least equal to the one of the element crossed, e.g., ventilation ducts EI t (i <-> o) t being the required resistance time for the crossed element.

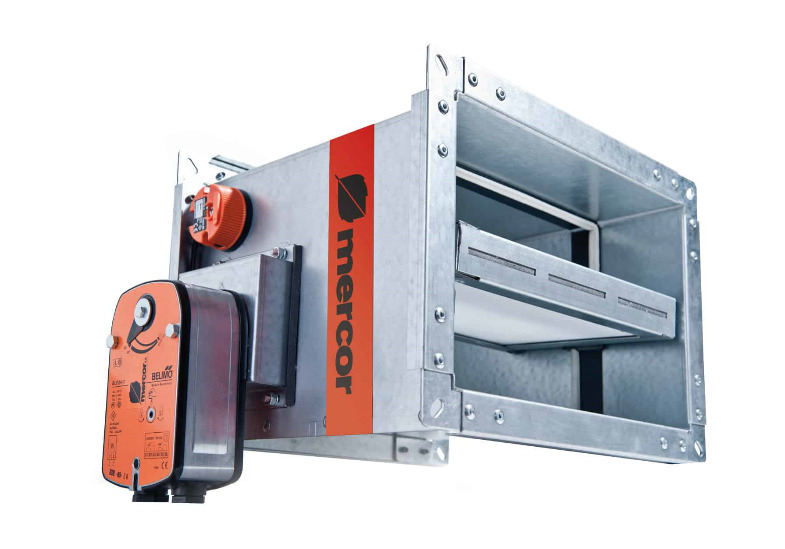

In previous posts we talked about option b) and fire-resistant ducts that pass through different sectors. We will now talk about point a) and more specifically about Mercor®’s automatic fire dampers. Let’s start with those that have a square or rectangular shape.

Fire dampers are elements that are installed when a ventilation duct passes from one fire sector to another. Generally, it operates by preventing the passage of fire and smoke from one sector to another thanks to an obstruction mechanism.

In Europe, since 2010, fire dampers have been regulated by the EN-15650 standard: “Ventilation of buildings. Fire dampers” and must have the CE marking. The tests must be carried out in accordance with the UNE EN 1366-2 standard: “Fire resistance tests of service facilities. Part 2: Fire dampers”. Its classification is obtained through the UNE EN 13501-3 standard: “Classification from data obtained during fire resistance tests of products and elements used in building service facilities: fire-resistant ducts and dampers”. Our fire dampers comply with these standards and have the CE Marking.

The fire dampers must comply with the usual criteria of integrity “E” and insulation “I” as well as the smoke-proof criteria “S“.

When it comes to our rectangular fire dampers, we have two categories:

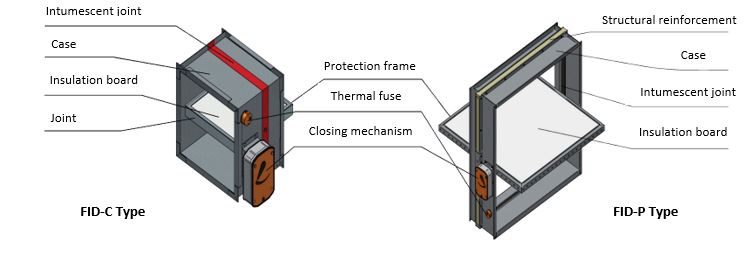

- FID-C fire dampers: These are the most simple and economical fire dampers, with a fire classification up to EIS-120. They are tested with dimensions up to 800 mm wide and 400 mm high.

- FID-P fire dampers: These dampers contain a structural reinforcement that gives them greater mechanical strength, with a fire classification also up to EIS-120, but with larger dimensions than the FID-C. Indeed, they are tested with dimensions up to 1500 mm wide and 1500 mm high.

Fire dampers are made of the following parts:

These dampers function under positive security, which means they close thanks to the force of a spring against which a fuse or a motor must fight in order to keep it open. This way, in the event of a power outage, the damper will always close precautionarily to prevent the fire from spreading. The mechanism that keeps them open can be:

- A bimetal thermal fuse

- A 24v DC motor

- A 220v AC motor

The reset of the dampers in the case of a false alert can be done both manually (with a handle) and electrically. There is also the possibility for the damper to send opening and closing signals to a central fire station.