Thermoacustic insulation and protection against fire of waffle slabs with tecwool mortar

Actualizado a fecha: 10 November, 2020

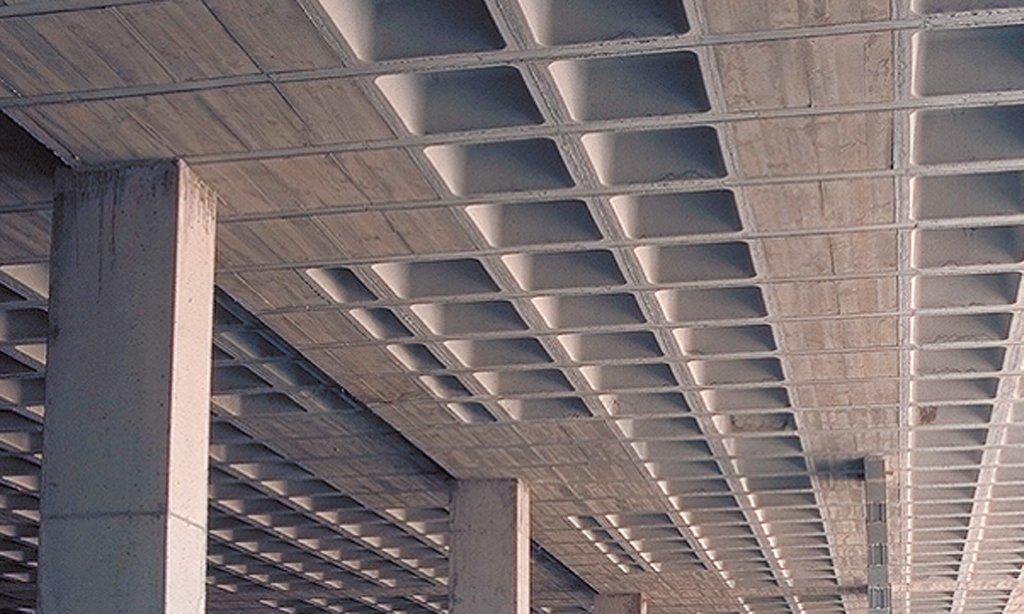

It is very common, during renovations or new constructions, to find this type of slab. It has the great advantage of letting more light in, between the pillars, but it also presents several disadvantages:

- A less effective thermal insulation than beam and block slabs.

- A less effective acoustic insulation due to a smaller thickness.

- Sometimes, a fire resistance that does not comply with the required standards.

Our R&D department developed two kinds of mortars to help us correct these three disadvantages:

- The Tecwool T® Mortar, offering an excellent thermoacoustic insulation. We can apply up to a 6cm thick layer and it has the EUROCLASS A1 label (NON-COMBUSTIBLE material, no contribution to fire).

- The Tecwool F® mortar, with very similar properties in terms of thermoacoustic insulation but that also acts like a protective layer by raising the fire resistance of a concrete structure up to REI-240 minutes.

Let us go a little bit further in the analysis of what our Tecwool F and Tecwool T mortars have to offer:

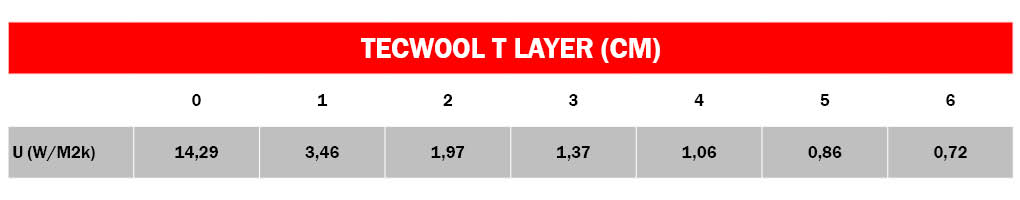

THERMAL INSULATION:

If the main purpose of the mortar application is the thermal insulation, we will use the Tecwool T® mortar. Less material will be needed, and the thermal insulation will be more effective than the Tecwool F which design is more oriented towards fire protection.

The Tecwool T® mortar presents a thermal conductivity of 0.0456 W/m·k

For a waffle slab of a total thickness of 3cm, the Thermal Transmittance U decreases according to the layer thickness of the Tecwool T applied to the structure:

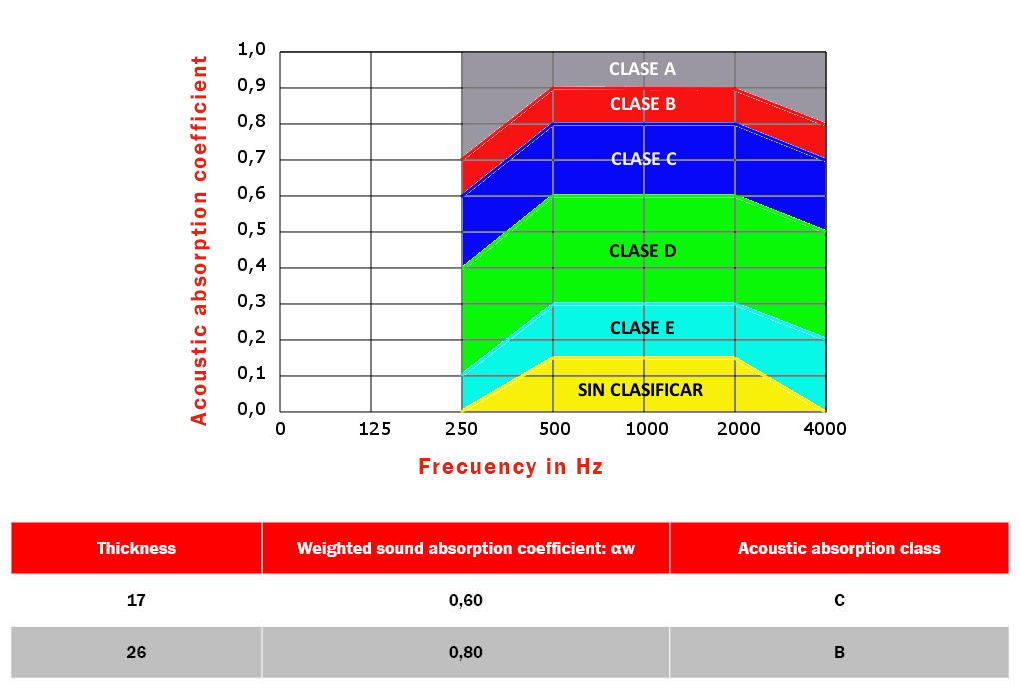

SOUND ABSORPTION:

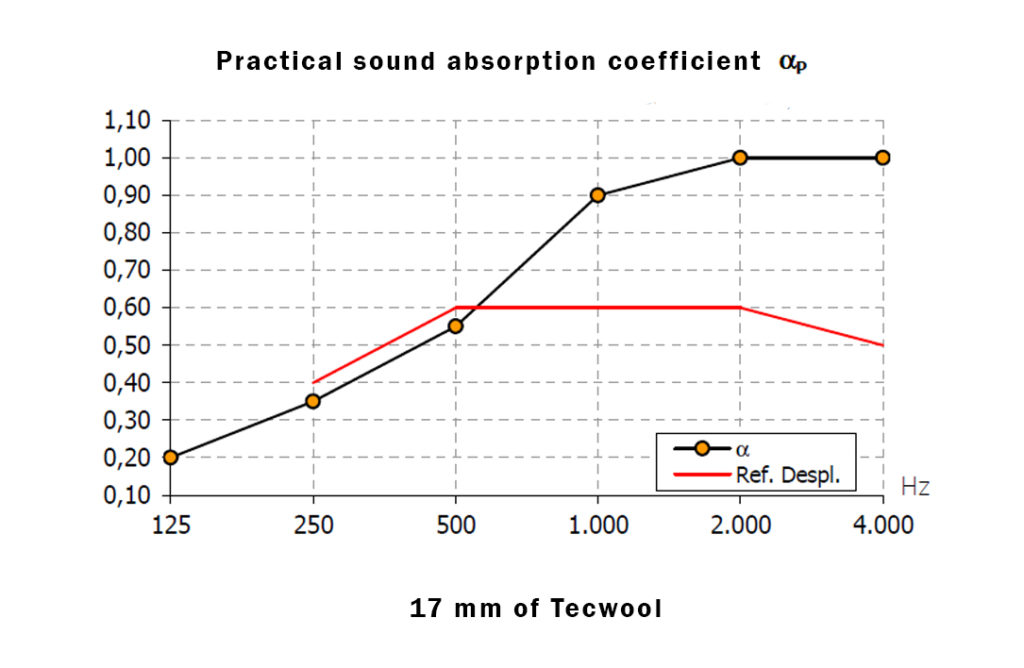

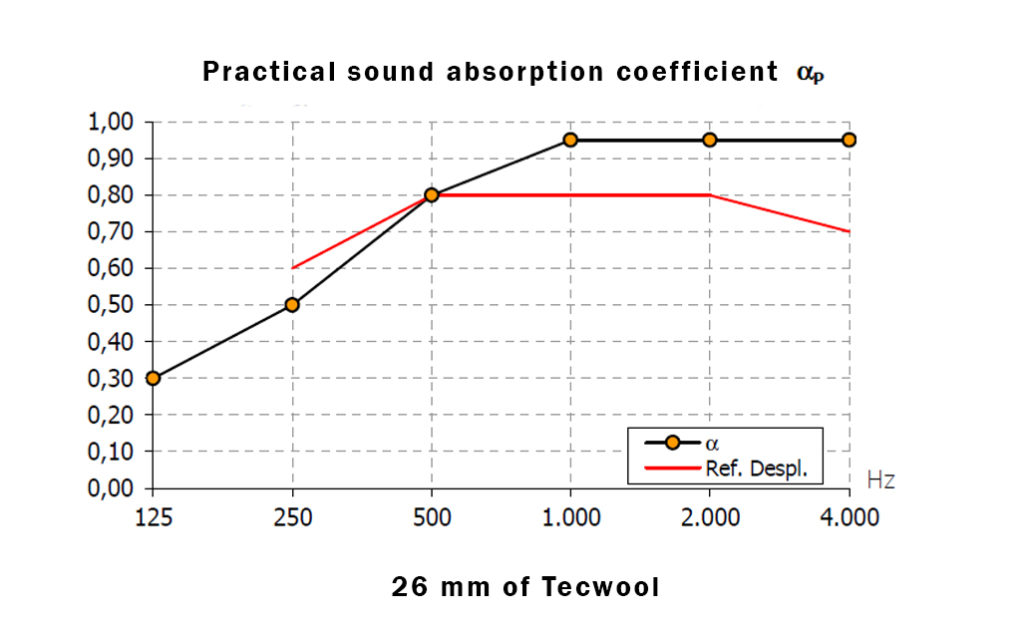

The Tecwool T® mortar efficiency comes from its polymorphic structure and from the porosity of its main constituent: rock wool. This efficiency is reinforced by its application via a pneumatic projection (allowing a continuous insulation without acoustic bridges and no disbondment risks), making it the ideal material for insulation against aerial noise of any surface. Tecwool T is tested according to the EN ISO 354 standard and the noise absorption coefficients required by the EN ISO 11654 standard are as follows:

In the following graphs, we can see how a 17 to 26 mm thick layer of Tecwool increases the sound absorption when the frequency intensity rises, even completely absorbing noises above 2000 Hz and 1000 Hz, respectively.

FIRE RESISTANCE:

Besides being an INCOMBUSTIBLE material, the mortar is often required to act like a protective layer to reinforce concrete when this one is facing a fire.

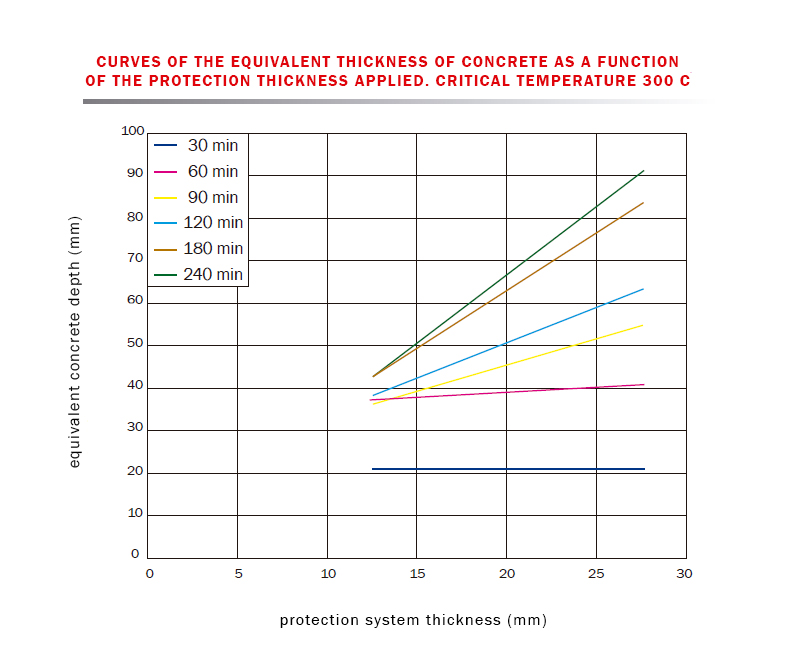

By realising tests to raise the fire resistance of a waffle slab that does not comply with required fire standards (in terms of thickness or distance to a metallic structure), we can find out how much mortar will be necessary to protect bearing concrete structures according to the UNE ENV 13.381-3 standard. The following graph shows the example of Tecwool F®:

For instance, if we want to reinforce a concrete structure to obtain a REI 120 (fire resistance during 120 minutes) of 120 mm, but this structure is only 60 mm, we will need to apply the equivalent of Tecwool F® mortar. In this case, the blue line tells us we will need to apply 26 mm of mortar.