Protection against fire of ventilation and extraction ducts

Actualizado a fecha: 10 November, 2020

When a ventilation duct goes through one or more fire sectors, the regulation is clear : it requires the installation of a shutter element at the penetration point to prevent the fire from passing through (for example, a fire damper), or the protection of the whole duct until its fire resistance is at least equal to the fire resistance of the partition wall separating the fire sectors. Today, we will talk about the latter.

In its section 3, the DB-SI establishes rules for the “Internal Propagation” :

The required fire resistance for compartmentalisation elements must be maintained where said elements are penetrated by installations such as cables, pipes, canalisations, ventilation ducts, etc. except for penetrations with a section inferior to 50cm2. To do so, one of the following options must be implemented :

a) Install an element that, in case of fire, automatically blocks the passage section and ensures a fire resistance at least equal to fire resistance of the compartmentalisation element, for example, an intumescent shutter device or an automatic fire damper EI t (i↔o), t being the required fire resistance time for the compartmentalisation element.

b) Crossing elements with a fire resistance at least equal to the fire resistance of the compartmentalising element, for example, ventilation ducts EI t (i↔o), t being the required fire resistance time for the compartmentalisation element.

We see, in addition of the concepts of Integrity and Insulation “EI” with the required corresponding time in minute, the symbol “(i↔o)”. Those initials mean inside and outside, and the bidirectional arrow indicates that the element must be resistant to fire both inside and outside of the duct.

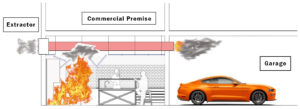

Let us illustrate those concepts with the following graphs, considering two possible fire situations and the ventilation duct of a garage going through a commercial premise without protection:

- Scenario 1 : Internal fire (i -> o) :

In this case, the fire starts in the garage, goes through the inside of the duct, attracted by the smoke extractor strength. The temperature increase inside the ducts makes it collapse little by little, quickly allowing the fire to spread in all of the commercial premise.

We clearly see here that the installation of a fire-resistant false ceiling in the commercial premise would not work as its support structure would be exposed to the fire and would also collapse during the first minutes of the fire.

Regrettably, lots of ducts are, still today, protected by fire-resistant false ceilings in spite of their lack of utility in this particular case.

- Scenario 2 : External fire (i <- o) :

In this second case, the fire starts in the commercial premise, reaches the false ceiling, and makes the duct collapse. Once the duct is destroyed, the fire easily goes through the wall and spreads inside the adjacent fire sector, the garage.

It is also necessary to be aware that a difference of pressures occurs inside the duct, due to the capacity of the fire to consume oxygen, causing its deformation. That is why the CTE establishes two types of standard tests for ventilation and extraction ducts :

- UNE 1366-1 : 2016 Tests for fire resistance of service facilities. Part 1: Ventilation ducts.

- UNE 1366-8 : 2005 Tests for fire resistance of service facilities. Part 8: Smoke extractor ducts.

To be able to approve and certify protection solutions against fire, it is necessary to carry out tests according to the regulation above and to carry out 4 different tests:

- Horizontal Duct Internal Fire

- Horizontal Duct External Fire

- Vertical Duct Internal Fire

- Vertical Duct External Fire

Once these 4 standard tests are completed according to the UNE EN 1366-1 standard, and to be able to certify a smoke extraction duct, another test needs to be carried out according to the UNE 1366-8 standard with a pressure resistance reaching up to 1.500 Pascals.

- Smoke extraction duct

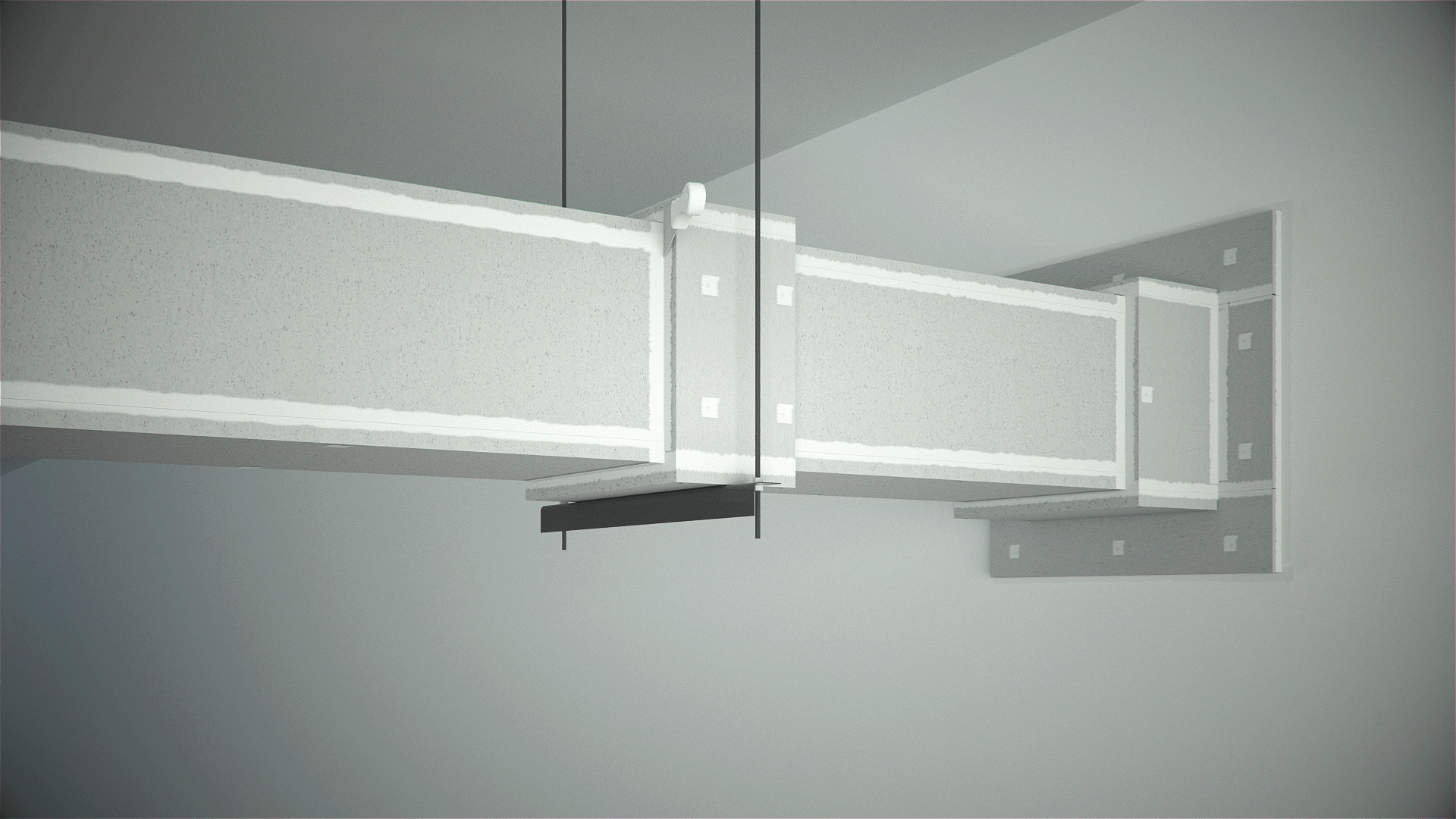

Our technical department at mercor tecresa® has developed several solutions to both reinforce the fire resistance of existing ducts and build ducts exclusively with our own material, always respecting the requirements of current regulations. The most common situation is the following :

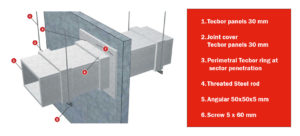

EI-120 duct with Tecbor panels of 30 mm :

Tested in horizontal and vertical position, internal and external fire, and for a smoke extraction up to 1.500 Pascals.