Intumescent Paint Application Guide

Steel used in construction needs to be protected against a possible fire. At a temperature close to 500 º C it loses its mechanical capacity and begins to twist. There are several ways to protect the steel, such as cover it with concrete, mortars or fireproof boards, including the possibility of applying an Intumescent Paint on the profile, to guarantees the maintenance of its load capacity , “R”, for a certain time.

We explain how to apply this kind of paint to obtain a guaranteed result.

A) BEFORE APPLICATION:

- The intumescent paint should not be applied directly on the steel without an antioxidant protection, since paint is a porous material and the rust will appear immediately. Usually, metal profiles already arrive at the work protected with a layer of antioxidant primer. Check the compatibility of the paint with that layer in the technical data sheet, to avoid undesirable reaction.

- In galvanized profiles it is necessary to place a previous fixer, since the surface of these profiles is not porous enough, to avoid adhesion problems. As in the previous case, it is necessary to verify the compatibility between the fixer and the intumescent paint.

- To obtain the paint thickness to be applied, we need to know the necessary Fire Resistance and the type of metal profile to protect. Each metal profile has a specific geometric factor called Massiveness, which can be obtained from data tables published on the internet. We will consider a critical steel temperature of 500 ºC to get the thickness value, generally expressed in microns, unless the Project Management tell us otherwise.

- Once the thickness is found, we need to know how much Intumescent Paint is needed on site. To do this, the theoretical performance is calculated and adjusted with a correction factor that depends on several factors.

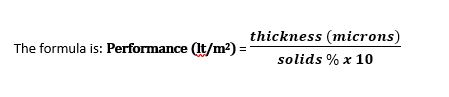

To calculate the theoretical performance we need to know the following values, that appear in the paint’s Technical Data Sheet:

- The solids percentage it contains.

- Its density.

- The thickness to apply, in microns.

This value indicates the liters of paint required to paint one square meter. Since this product is normally supplied in kg, the resulting value must be multiplied by the density of the product and the surface to be painted, in order to obtain the theoretical kg of paint required.

Paint (kg) = Th performance (l/m2) x Density (kg/l) x Suface (m2)

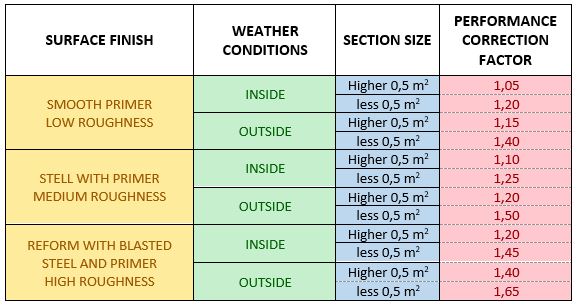

In practice, this value must be multiplied by a correction factor that depends on several circumstances, being the most important the following ones:

- Roughness of the surface to be painted.

- Application method (airless gun, brush or roller).

- Profile size and width of the jet of the airless gun.

- Wind, if we paint on the outside.

All these factors influence the theoretical performance (performance under ideal conditions) increasing the consumption of Intumescent Paint. This is quantified with a correction factor ranging from 1.05 in smooth steel with primer painted in the workshop, up to 2 in the case of airless painting outside on a windy day. This last option can be ruled out, since “you should never paint outdoors in the wind”, due to the likely damage caused to nearby cars and buildings. Only experience allows adjusting the correction factor. The following table approximates some values as a guide to assess the material needed to paint using an Airless Gun:

When the circumstances are unknown, it is necessary to be conservative and put a correction factor of 1.4 to avoid unpleasant surprises.

EXAMPLE:

We are asked to apply intumescent paint R-30 to the following metal profiles inside a reform:

Three frames consisting of a 5 m IPE 370 beam, to be painted on 3 sides, and two SHS 100×5 mm square pillars, 3 m high, to be painted on four sides.

We obtain two values from each profile from the structural handbook: the development and the massiveness:

- IPE 370 beam has a 3-sided development of 0.91 m and a massiveness of 197 m-1

- SHS 100×5 square pillars have a 4-sided development of 0.4 m and a massiveness of 211 m–

With the formula above, the surface to be painted is obtained:

Beams: 3 units x 0.91 m development x 5 m = 13.65 m2

Pillars: 6 units x 0.4 m x 3 m = 7.2 m2

Once the intumescent paint is selected (we recommend our Teclack®-W Intumescent Paint), the test tables should be consulted to obtain the thickness in microns for a critical temperature of 500 ºC: X

Consult technical data sheet of our Teclack®-W paint by clicking on the link.

For beams, the “open profiles” table must be consulted. For R-30 and 197 of massiveness a thickness of 471 microns is required.

For pillars, the “closed profiles” table must be consulted. For R-30 and 211 of massiveness a thickness of 250 microns is required.

To calculate the Performance of each profile, two data from the data sheets are necessary: solids percentage and the product density. For our Teclack-W Paint these data are: 68% and 1.34g/cm3 (kg/l).

For beams: Theoretical Performance = 471 microns / (68% x 10) = 0.69 l/m2 and to know the kg needed: Theoretical kg = 0.69 l/m2 x 1.34 kg/t x 13.65 m2 = 12.67 kg.

For pillars: Theoretical Performance = 250 microns / (68% x 10) = 0.37 l/m2 and to know the kg needed: Theoretical kg = 0.37 l/m2 x 1.34 kg/l x 7.2 m2 = 3.54 kg.

When calculating the Real Consumption, the correction factors are different for each element. There is more waste when painting pillars than beams, since part of the paint jet when applied by airless gun goes outside the pillars.

For beams the correction factor must be 1.10 and, for pillars, 1.45, so the final result is: (12.67 x 1.1) + (3.54 x 1.45) = 19.08 kg of Teclack -W® Paint.

B) DURING THE APPLICATION:

- Its application by Airless Spray is recommended to improve uniformity in application and finish. Being able to apply by brush or roller in an exceptional way.

- In the case of our Teclack-W Paint, it can be diluted by a maximum of 3% in water to improve its viscosity by mixing the product with a mixer. Other paints may require other types of solvents.

- This product should not be applied below 3ºC or above 40ºC and care must be taken with profiles exposed to the sun as they can reach high temperatures that can cause problems with paint.

- It must be applied in layers or coats of 250 – 300 microns and when the thickness is greater, allow to dry between coats 8 hours and 24 hours for the final coat of sealer or enamel.

- For the application of our Teclack-W Paint by means of an Airless Gun, we recommend a nozzle between 0.48 and 0.63 mm.

- The use of appropriate PPE is mandatory for the application of this type of products, such as masks, hermetic glasses and protective gloves.

C) AFTER THE APPLICATION:

- Once the Intumescent Paint has been applied, the pore must be sealed using a finishing enamel, since this product adsorbs humidity from the environment and degrades, losing its intumescent properties in a very short space of time, aggravating this circumstance in humid environments. It must be verified in the technical data sheet that the sealing product is compatible with Applied intumescent paint.

- Note that these Intumescent products do not maintain their properties forever and may degrade over time. This process will depend on how the product has been applied, under what conditions and on its finishing or sealant layer.

The administration must regulate the maintenance of “All” Passive Protection Installations, just as the RIPCI does with Active Fire Protection and Smoke Evacuation Systems. It is especially evident in this type of reactive products that we know have a “limited useful life”. However, the Product Installation Certificate has no expiration and can be valid forever, so in practice they are not maintained and are reinstalled when the useful life of the product has ended, putting in real danger the evacuation in case of fire due to the collapse of the structure.