Passive Protection In Industrial Building – Part 2

Continuing with last week’s Post, today we finish with the concerning to passive protection in Industrial Buildings.

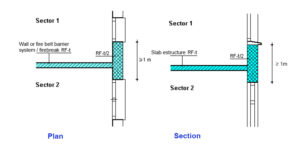

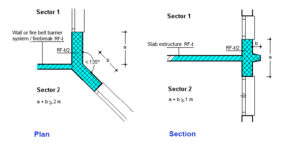

Encounter of dividings walls with facade partition:

When a dividing wall meets a facade, it must have a fire resistance equal to half the fire resistance of the dividing wall at a distance of 1 m measured in vertical projection. It´s necessary to verify that it´s fulfilled mainly in nest type buildings in the access facade and to measure well the distance of the entrance doors with the adjacent building.

Also, although less frequent, when the dividing wall meets the façade and the latter makes a break of less than 135º, the fire resistance must be half of the dividing wall as in the previous case, but the distance is increased to 2 m. If there are fire-resistant projections, we can reduce the distances in the length of the projection.

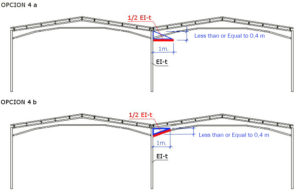

Encounter of fire belt barrier system / roof firrebreak:

As it happens with the dividing walls on the façade, when a dividing wall undertakes a non-fire resistant roof between two fire sectors or two different activities, it must have an element with half the fire resistance of the dividing wall in a distance of 1 m measured in horizontal projection.

This element commonly called firewall strips would be installed in these four ways:

1.- To have an overhang above the roof (1 a), or that the roofs have a distance greater than 1 m measured vertically between them (1 b), always this element with a fire resistance half of that required for the dividing wall.

2.- To have an element that replaces the roof panel in that stretch with half of the fire resistance of the dividing wall anchored to belts with the same fire resistance as the strip. Here aren´t valid materials projected or attached directly to the roof panel because this would not be stable in a fire.

3.- Another solution is to anchor to belts, here we have to make sure that the fire resistance of the belts and the support beam is the same or higher than that of the strip.

4.- If we don´t know the fire resistance of the belts we will anchor to the dividing wall with a self-supporting structure, this structure must be tested under the Protocol of Testing of fire belt barrier system or a low test of false ceiling placed as such and it is arranged in this one. There are two possibilities: horizontal strip (4.a) and sloping strip (4.b). These two systems will be obligatory depending on the obligation of the standard of a maximum distance of 0.4 m from the lower part of the starting point of the roof.

This will only be done in these ways as long as the adjacent building cannot be accessed because it belongs to another owner who is not required to do so because he has a project of activity prior to the RDSCIEI of 2004. When this circumstance disappears due to a change of activity or reform, another meter must be built in the adjacent building.

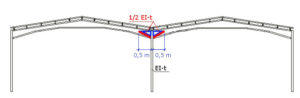

In all other cases, the firebreak strip must be divided equally between the two fire sectors as shown in the graph:

Our Technical Department has developed several solutions for this type of strip, the most common being a Nervometal-type mesh with subsequent application of Tecwool® F mortar and another with Tecbor® Y Boards, the first being very quick and economical and the second having a better finish:

As always, special care will be taken to carry out a correct sectoring of gaps and installation passages between two fire sectors, sealing the passages as we have already commented in previous Post with Tecsel® Sealing Systems.

For industrial installations with risk of deflagration, such as the Petrochemical Industry, there is no specific regulation on this matter, so we work with American regulations. The most common is to work with other types of materials that are more mechanically resistant to explosions and with another heating curve, such as the American Hydrocarbon UL-1709. Mercor Tecresa® has developed specific products for these cases, such as the Tecwool® 825 Mortar and has carried out many tests with this type of Hydrocarbon curve, such as the Cable Tray Fire Protection with Tecbor® Joint Paste ready to use.