Smoke Exhaust Systems in industrial buildings

As it happens with the Passive Protection of the structure, sectoring of dividing walls and firewall strips, when applying the Fire Safety Regulations in Industrial Establishments (RSCIEI), we must carry out a Temperature Control and Smoke Exhaust Systems Installation (in industrial buildings) whenever the intrinsic risk of the activity is Medium or High, independently of the surface that the building has.

For this purpose, point 7.1 of the Regulations states:

They shall have a Smoke and Heat Control System designed according to UNE EN 23.585:

a) Sectors with production activities:

1.º Of average intrinsic risk and built area > 2000 m2

2.º High intrinsic risk and built area > 1000 m2

b) Sectors with storage activities:

1.º Of average intrinsic risk and built area > 1000 m2

2.º High intrinsic risk and built area > 800 m2

For the smaller surface buildings of medium and high risk also it is forced to carry out a System of Control of Smoke and Heat, the only thing that changes is that it gives us some values of calculation generally more favorable than if we calculate them following the norm UNE EN 23.585 that they are:

a) The sectors with production activities for medium or high intrinsic risk buildings at a rate of:

– 0.5 m2 of Aerodynamic Evacuation Surface for every 150 m2 or fraction thereof if the sector is below ground level.

– 0.5 m2 of Evacuation Aerodynamic Surface for every 200 m2 or fraction if the sector is above ground.

b) Sectors with Storage activities for medium or high intrinsic risk vessels at a rate of:

– 0.5 m2 of Evacuation Aerodynamic Surface for every 100 m2 or fraction if the sector is below ground level.

– 0.5 m2 of Evacuation Aerodynamic Surface for every 150 m2 or fraction if the sector is above ground.

Another very important aspect establishes that “Ventilation will be Natural whenever the location of the sector don´t prevents it; in that case it may be forced”. So this obliges us to install ventilators, except in cases where it is impossible to place them, such as in a low-level sector (basement) without the possibility of natural ventilation.

It also mentions that the ventilators must be distributed uniformly in the fire sector and be able to be opened both “manually” (by the extinguishing services) and “automatically” (connected to the fire detection). Regarding the air supply, it is also mentioned that they must have air inlets under the tank with the same aerodynamic surface as the outlet and that access doors may be computed for this purpose, provided that they are automated and connected to the detection.

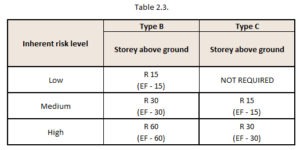

Somewhat less known, is that for low risk buildings, sometimes it can be interesting to make a system of smoke and temperature control, although it is not required by law. This comes from Point 4.2. which gives us a less restrictive table 2.3 of fire resistance of the structure for above-ground buildings with lightweight roofs:

So for C type and Low Intrinsic Hazard buildings we may not justify the fire resistance of the structure if it has a Smoke and Heat Control system and this sometimes compensates for having to fireproof the structure, if the building is in production or is more expensive economically.

If this industrial installation is of high or medium risk and goes beyond the surfaces mentioned above, so the calculations of Smoke Evacuation Surface must be made by means of the UNE EN 23.585 standard, from Mercor Tecresa® Technical Department we offer the possibility of making these calculations without any kind of commitment, as it is a rather complex standard for those who have not usually worked with it, and thus achieve an optimal and effective smoke exhaust systems in industrial buildings in case of fire.

For the purposes of designing the smoke Exhaust systems in industrial buildings installation, it is appropriate to point out two important aspects that substantially modify the calculation.

- Space must be left for storing smoke: In the case of storage at height, the layer of smoke cannot go down more than half a metre above the last goods stored to avoid the Flash Over effect and the fire spreading throughout the whole building. In many cases we find storage designs up to practically the roof that make an installation unfeasible due to the large number of exutories required. It is convenient to leave enough space to store smoke and make the system work. In addition, the more space we leave behind, the fewer ventilators will be needed and the more we will save in such an installation.

- In the case of natural ventilation, the smoke rooms should not exceed 2,000 m2 or 60 m.l. on their longest axis. If these measures are exceeded, several smoke ventilators must be installed, with the consequent extra cost of doubling or tripling the number of ventilators calculated for one ventilator. In the design phase of the industrial installations it is positive to know these limitations in order to try to make the smoke deposits proportional to the fire sectors in those cases where it is possible and thus optimize the installation.