What’s the fire resistance of a construction material?

The Fire Resistance of a construction material is defined by several independant components that can be used individually or together, depending on the use given to said material.

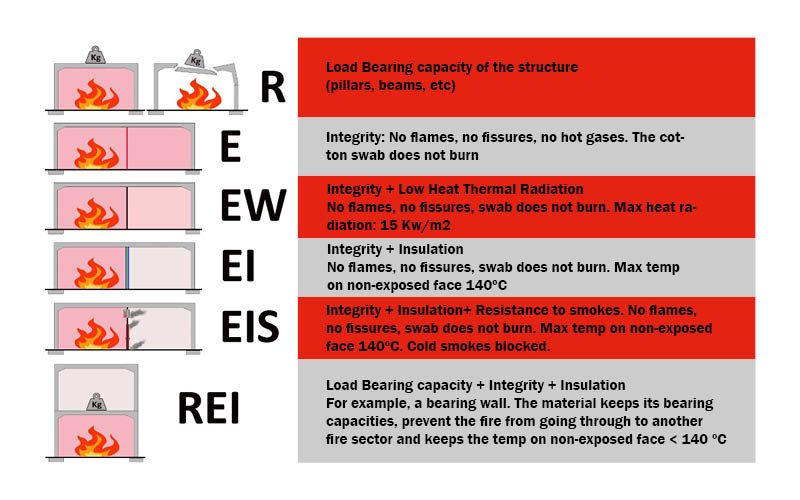

Those components are :

- R (from “Resistance”): It is the “Load Bearing Capacity” of structural elements like pillars, beams, slabs, bearing walls, etc. It is defined by measuring the time that the material can sustain its bearing function when submitted to a standard time-temperature curve type test.

- E: The “Integrity”. Usually associated with sectoring elements like partition walls, doors, ceilings, etc. It is the material’s ability to resist to fire exposure while, at the same time, preventing the passage of flames or hot gases that could produce the ignition of the non-exposed surface of the material. Three methods are used during a standard time-temperature curve type test:

- Measuring the cracks and fissures that appear during the test. They have to remain smaller than a certain dimension.

- Placing a cotton swab near the cracks and fissures. The test is valid if the swab doesn’t burn.

- There can’t be any sustained flaming on the non-exposed surface of the material

- I: The “Insulation”. It marks the difference of temperatures between the surface exposed to fire and the non-exposed one. Usually, the non-exposed surface should not go over 140ºC when the exposed one is submitted to a standard type test of over 1000ºC.

These components are the common ones, but, in specific cases, there are a few others:

- W “Low Heat Thermal Radiation”, also associated with sectoring elements. It indicates that the heat going through these elements via thermal radiation cannot go over 15Kw/m2

- S (from “Smoke”). In the definition of the Integrity we talked about preventing flames and hot gases to go through the material. Here we add a smoke-proof component so that the cold smoke cannot go from a fire sector to another. It is important, for example, when working with fire dampers.

- M “Mechanical action”. It is the ability of the sectoring element to handle the impact of another element that would fall on it during a fire.

- C “Automatic Closing”. Applies to automatic closing systems like automatic closing fire doors, that exclusively close when a fire is started.

- G “Soot Fire Resistance”. Applies to chimneys and braziers.

- K “Protection abilities in case of fire”. Referring to the ability of a protective coating to prevent from ignition, carbonatation or other possible damages in case of fire.

- P “Electrical Continuity”. Used when there is a need to protect electric cables and ensure they keep working through part of the fire.

All these terms are followed by the number of minutes they should resist for. In the European union, those times are: 15, 20, 30, 45, 60, 90, 120, 180, 240 and 360 minutes.

Hereunder are graphic representations to help us fully understand the main concepts.