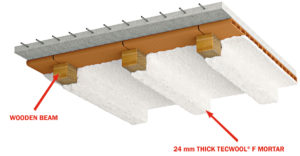

Wooden beams protection with Tecwool® F Mortar

One of the most common uses of our fireproof Tecwool® F mortar, besides the fire protection of metal and concrete structures, is the protection of structures with wooden beams. This circumstance frequently occurs in renovations and buildings in old city centres. When changing the use or proceed to the renovation of the building, we can find under the suspended ceilings a typical early twentieth century slab made with wood logs, a beam filling block of hurdle and gypsum and a small compression upper layer.

Wood is a material that withstands high temperatures very well, unlike other construction materials that seem to have a better fire behavior, such as concrete and iron. The disadvantage of this construction material is that it is combustible and that its carbonation produces a loss of section that, finally, causes the collapse. If we prevent wood from burning, it will withstand very well the high temperatures of a fire.

A thin layer makes the difference

In order to get this, we have renewed the test for the protection of wooden beam slabs. With a thickness of only 24 mm of Tecwool® F mortar, we have achieved an “R” bearing capacity of 180 minutes beams (140×140 mm). As a reference of the good behavior of the wood, to protect an IPE beam of the same characteristics (IPE 140) we would need a 53 mm thick coating of the same material. In the case of concrete, the beam should have an edge of 400 mm and a distance of 75 mm from the face exposed to fire to the armor to be able to withstand those three hours of fire resistance.

To meet both the “R” (bearing capacity) of the beams and the Integrity “E” and the insulation “I” (REI-180) we must have a slab with these two factors:

- Wooden joists of 140×140 mm or more.

- A compression layer equal to or more than 50 mm.

Once we comply these requirements, we can protect the structure from fire up to three hours and also as a compartmentalization element by spraying the 24 mm thick layer of Tecwool® F mortar. Prior to the application, we have to cover the wood with chicken wire or nervometal mesh, since timber is a poor support due to its bad adherence.

It is a perfect solution for renovations because of its low cost. Besides, comparing with other systems made by fireproof gypsum boards, this solution allows us to make easier electric installations between the mortar and the decorative suspended ceiling without fearing a fire. When using boards systems as suspended ceilings we have to be extremely careful with the installations on top that could generate a fire where a combustible unprotected wooden slab is placed in.