Fire protection of concrete slabs with EPS arches

The concrete slabs with polystyrene arches have great advantages: a better thermal insulation, lightens the own weight of the slab, fast placement and economic price, but what happens with its fire resistance?

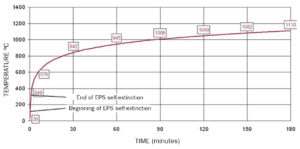

The polystyrene arches are made of expanded polystyrene, more technically known as EPS. Like all organic materials, it is combustible, propagates flames and releases smoke and fumes during its combustion (mainly carbon monoxide and styrene). To restrict this performance, a new product has been created with the addition of ignition retardants, achieving the “SE” class. This product shrinks back from the heat source (self-extinguishing) and the decomposition of the additive generates a gas that retards the propagation of the flame on the plastic surface. The material is easily to recognize: when approaching the flame of a lighter, a hole is generated around it and it does not continue burning. The normal EPS burns and gives off a black smoke.

Normally, this material is protected with a plaster trim on the underside to protect it from fire and show a better finish. Plastics, as a rule, have poor adhesion to coatings. These vaults have wedge-shaped grooves in which part of the coating material is introduced as an anchoring.

Related:

Poor fire protection

The fire performance of this coating retards its combustion. However, in a few minutes and as soon as it reaches 80-100ºC, the plastic begins to soften, the plaster to crack and precipitate to the ground, which leaves the EPS directly in contact with the flame. This material will start to burn or, in the best case, to self-extinguish leaving the beams, joists and compression layer as the only element that prevents the fire from passing to the upper floor or the collapse.

Sometimes, once the plaster trim has been applied, the fire resistance performance of the slab has been treated according to the DB-SI (Spanish regulation) as if it were a conventional unidirectional slab of ceramic or concrete slab. We have to be very careful, since it is not, and the Building Technical Code does not treat them the same way.

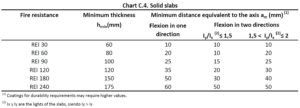

After all, the prompt disappearance of the EPS will leave the joists and the compression layer exposed to the flames and the fire resistance of the slab will depend on the distance of the face exposed to the reinforcements and the thickness of the compression layer, since the latter will have to comply with table C-4 of the DB-SI if its function is delimiting the fire, as usual.

A concrete slab with EPS arches with a 50 mm compression layer will not even give us REI-30, since it needs a 60 mm thickness layer for that resistance to fire.

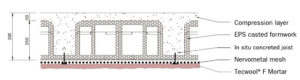

An additional fireproof solution

To solve this problem and achieve the required fire resistance, we have developed at mercor tecresa® several solutions. The most common is the placement of a nervometal mesh anchored to the concrete joists and project Tecwool® F or Tecplaster® mortars with enough thickness according to the test to meet all the requirements that DB-SI marks us for this type of slabs.

In this particular case, the EPS arches also have the disadvantage of providing poor acoustic insulation, especially airborne noise. For this reason, we always recommend the Tecwool® F mortar, as it provides excellent acoustic insulation, as it is a Class B Acoustic Absorption material with a thickness of 26 mm according to EN ISO 354.